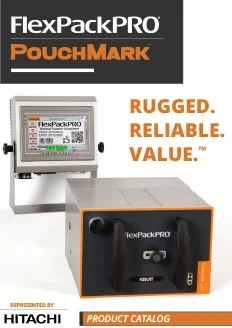

Unlock the potential of your production line with FlexPackPRO’s thermal transfer overprinting (TTO) technology. This ribbon mode system prints real-time variable data, barcodes, machine-readable codes, texts, graphics, and logos on flexible packaging films and labels, thereby reducing waste, downtime, and costs.

The FlexPackPro TTO printer series operate in both continuous and intermittent modes, adjusting print widths and speeds with precision based on your needs. These printers can be seamlessly integrated into packaging and processing equipment, including labelers, tray sealers, and flow wrappers for enhanced product traceability.

Ideal for both vertical and horizontal form, fill, and seal machinery installations, our industrial TTO printers deliver clear, sharp codes on a variety of substrates, including PD, PP, paper, and Tyvek®, without compromising production line speeds.

Low resolution case coding can print up to 2 lines of text

High resolution case coding is ideal for printing logos, images and bar codes

Coding on corrugated cases or shrink-wrapped cases dry on contact to eliminate fading or smearing/bleeding

Case coding printers can print both horizontally and vertically

Thermal Transfer Overprinters are used for both vertical and horizontal form, fill and seal machinery installation requirements. They create codes and information on a variety of substrates, including PD, PP, paper and Tyvek. The results are clear and sharp codes that are created without compromising production line speeds.

Our Range of TTO Printers

-

32mm (1.3”) wide, 300dpi Printhead

32mm (1.3”) wide, 300dpi Printhead

-

Continuous & Intermittent Motion

Continuous & Intermittent Motion

-

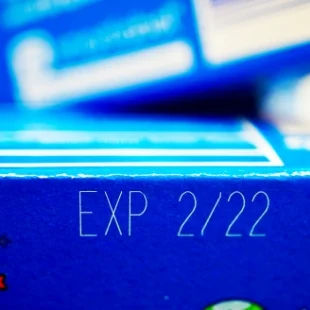

Perfect for “small footprint” expiration dates and lot codes

Perfect for “small footprint” expiration dates and lot codes

-

Economical digital upgrade from hot stamp printers and roller coders

Economical digital upgrade from hot stamp printers and roller coders

-

Recommended for both packaging machines and labelers

Recommended for both packaging machines and labelers

-

53mm (2.1”) wide, 300dpi Printhead

53mm (2.1”) wide, 300dpi Printhead

-

Continuous & Intermittent models

Continuous & Intermittent models

-

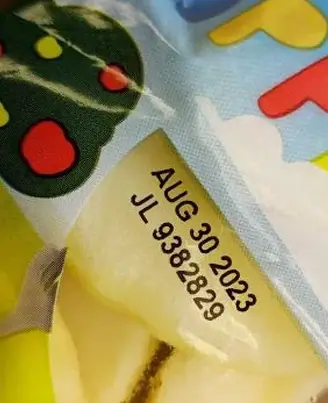

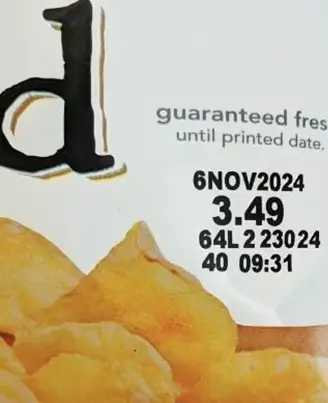

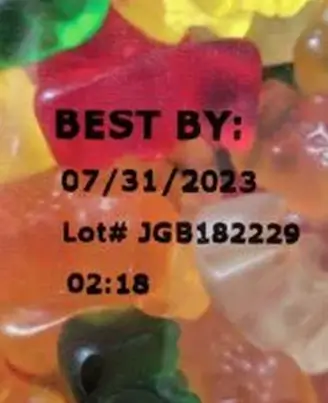

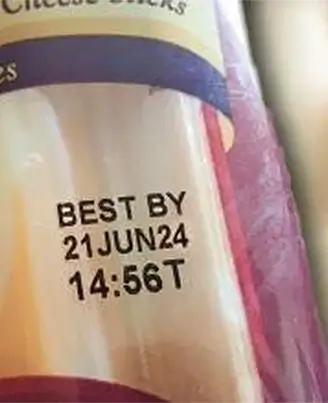

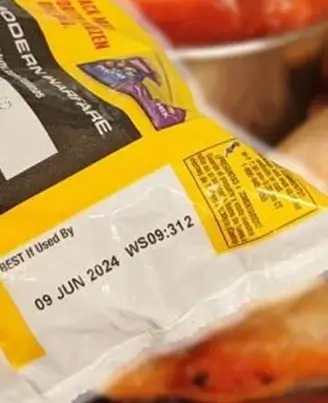

Print “press quality” Best By dates, lot codes, barcodes, text and graphics

Print “press quality” Best By dates, lot codes, barcodes, text and graphics

-

High-speed performance for heavy-volume applications

High-speed performance for heavy-volume applications

-

Superior, cost-effective replacement for other brands of TTO

Superior, cost-effective replacement for other brands of TTO

-

107mm (4.2”) wide, 300dpi Printhead

107mm (4.2”) wide, 300dpi Printhead

-

Continuous & Intermittent models

Continuous & Intermittent models

-

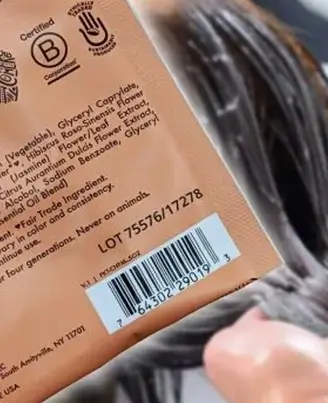

Print larger combinations of codes, logos, text, and graphics

Print larger combinations of codes, logos, text, and graphics

-

An excellent option for printing variable ingredients and nutrition panels

An excellent option for printing variable ingredients and nutrition panels

-

Up to 4.2” x 10” print area

Up to 4.2” x 10” print area

-

128mm (5” wide), 300dpi Printhead

128mm (5” wide), 300dpi Printhead

-

Continuous & Intermittent Motionels

Continuous & Intermittent Motionels

-

Largest Available TTO Print Area (5” x 8”)

Largest Available TTO Print Area (5” x 8”)

-

Fit logos, barcodes, date codes, ingredients, nutrition statements, and more in one template

Fit logos, barcodes, date codes, ingredients, nutrition statements, and more in one template

Specialty Features

Explore the unique features and benefits of our high-performance TTO printers.

Can choose from either compact or full-size TTO printers

Can choose from either compact or full-size TTO printers

Can choose from either compact or full-size TTO printers

Can print a variety of information, including 2D barcodes and logos on most packaging materials

Can print a variety of information, including 2D barcodes and logos on most packaging materials

Can print a variety of information, including 2D barcodes and logos on most packaging materials

Capable of printing in either continuous or intermittent modes

Capable of printing in either continuous or intermittent modes

Capable of printing in either continuous or intermittent modes

Can print without factory air and at a variety of temperatures

Can print without factory air and at a variety of temperatures

Can print without factory air and at a variety of temperatures

Durable, user-friendly 7” Stainless steel touchscreen controllers

Durable, user-friendly 7” Stainless steel touchscreen controllers

Durable, user-friendly 7” Stainless steel touchscreen controllers

Can integrate with other components of your production line by simply adding a dedicated controller

Can integrate with other components of your production line by simply adding a dedicated controller

Can integrate with other components of your production line by simply adding a dedicated controller

Operating temperature 1° - 55° C (34° - 131° F)

Operating temperature 1° - 55° C (34° - 131° F)

Operating temperature 1° - 55° C (34° - 131° F)

Common Printing & Packaging Applications

Explore the diverse industrial applications of our thermal transfer overprinters for precise variable data printing on various flexible packaging materials.

TTO Printers by Industries

Discover the unmatched capabilities of our thermal transfer overprinters, setting the standard for precision coding across a broad spectrum of industries.

Helpful Resources

Put your production on the fast track with our feature-rich CIJ printers. Explore our extensive collection of resources, offering informative product videos, detailed brochures, technical specifications, and inspiring customer success stories.

Speak to Our Experts

Call our Toll-Free number for expert guidance on choosing the best marking and coding equipment to meet your diverse industrial printing & packaging application needs.

Get in Touch

Hitachi Industrial Equipment & Solutions America (HIESA) has sales offices strategically located in the Midwest and West Coast regions that specializes in providing primary and secondary packaging equipment and solutions. Beyond our immediate vicinity, we have a wide network of authorized sales partners that we work closely with to ensure that our packaging solutions are accessible to a broader customer base across the Americas and Canada.

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

English

English