Behind every smoothly running engine, every flawlessly assembled chassis, lies a critical yet often overlooked aspect of automotive manufacturing: marking and coding. As a reliable coding partner, Hitachi enables automotive manufacturers to drive efficiency and quality assurance through unparalleled accuracy in direct part marking and inkjet printing on a variety of materials used throughout the automotive manufacturing process in the most challenging environments, while fueling business growth with maximum throughput.

Key Industry Challenges

In the fast-paced automotive realm, challenges such as stringent regulations and increasing demand for auto parts traceability demand highly reliable coding solutions. To tackle these challenges head-on, Hitachi offers its robust UX2-Dynamic Continuous Inkjet (CIJ) Printer along with Vision Systems & other marking & coding solutions that seamlessly integrate into the manufacturing processes, ensuring compliance, efficiency, and unparalleled performance.

The Need for Efficient Pigment Printing

Overcoming Print Speed Challenges in Automotive Part Production

Ensuring efficient automotive part production processes can be challenging when maintaining print speeds with pigment inks, which often require additional attention. Hitachi addresses this challenge with the UX-Pigment CIJ Printer, featuring an innovative airless stirring mechanism that prevents pigments from settling while also reducing evaporation. Combined with our diaphragm pumps, this design reduces strain on the printer, resulting in less downtime and lower maintenance compared to traditional pigment-based printers.

Ensuring Durability: Overcoming Ink Degradation in Harsh Automotive Environments

Inks that need to endure exposure to extreme temperatures and fluid solvents such as brake fluids, gasoline, antifreeze, and oil

In the automotive industry, products endure harsh conditions, from extreme temperatures to exposure to moisture and chemicals. Exposure to harsh substances like brake fluids, oil, etc. can degrade markings over time, leading to illegibility and compromised traceability, ultimately impacting product quality and safety. Hitachi addresses the challenge by employing fade-resistant, high-contrast pigmented inks, including white, blue, yellow, and orange colors. Designed for durability, these inks ensure markings remain intact throughout the product's lifecycle, offering reliable identification and traceability for automotive components.

Overcoming Production Challenges

Dust particles and debris can accumulate on surfaces, hindering print clarity and legibility

Achieving clear and precise printing for lines of text, 2D and linear codes, and graphics poses a significant challenge, especially in a variety of automotive manufacturing environments. Hitachi's UX2-Dynamic CIJ Printer offers a solution with its patented Ink Guard, extending printhead cleaning intervals and boosting uptime. Additionally, the printer's Enhanced Dot Control Algorithm ensures accurate and high-quality prints across various surfaces and production speeds, overcoming these hurdles seamlessly. Our printer integrates seamlessly into your production lines, providing operators with an intuitive user interface, ensuring swift implementation and minimal downtime for next-level productivity.

Streamlined Code Verification

Ensuring Quality & Traceability in Automotive Manufacturing

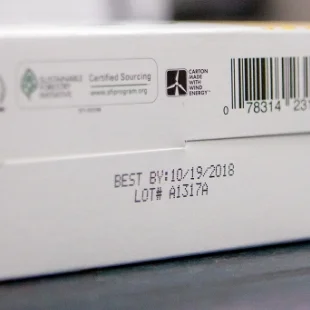

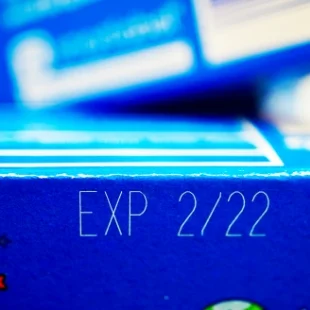

In the automotive industry, accuracy in printed codes is essential for quality control, traceability, and compliance. Hitachi's MC-20 Vision System revolutionizes code verification, integrating Optical Character Verification (OCV) technology with Continuous Inkjet matrix printing. This system meticulously inspects each character, flagging deviations instantly. With real-time quality control, it minimizes downtime by alerting operators to performance issues, ensuring seamless efficiency and productivity.

Common Printing & Packaging Applications

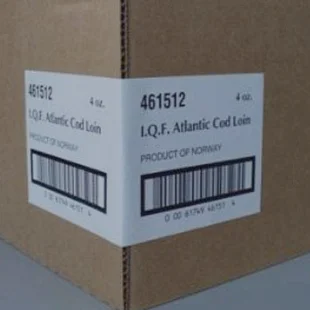

Accelerate your production line speed while ensuring traceability, compliance, and efficiency with our resilient and reliable automotive marking and coding solution that adapts seamlessly to diverse materials and components, from printing on metal parts to rigid plastics.

Helpful Resources

In an industry where precision and efficiency reign supreme, you need a date coding solution that works as fast as you do, without compromising on quality. Put your production on the fast track with Hitachi. Explore our collection of informative product videos, downloadable industry guides, and inspiring customer success stories from the Automotive sector.

Why Choose Hitachi CIJ Printers

With an illustrious history of over four decades in industrial equipment and solutions, Hitachi is your esteemed partner for precision marking and coding solutions. Our unwavering commitment to quality, safety, and sustainability underpins the reliability of Hitachi Continuous Inkjet (CIJ) printers for variable data printing and other industry-specific marking and coding requirements. Fueled by advanced technology and continuous innovation, we offer unmatched customer support to help you boost production uptime and achieve operational excellence.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

Dairy

Dairy  Construction

Construction  Meat & Seafood

Meat & Seafood  Cosmetic

Cosmetic  Bakery

Bakery  Candy & Confectionary

Candy & Confectionary  Canning (Foods)

Canning (Foods)  Beverage

Beverage  Egg

Egg  Electronics

Electronics  Tobacco & Cannabis

Tobacco & Cannabis  Wire & Cable

Wire & Cable  Pharmaceutical & Medical

Pharmaceutical & Medical

English

English

Portuguese

Portuguese

Spanish

Spanish