The pharmaceutical and medical industry operates within a landscape rife with stringent regulatory frameworks. However, achieving accuracy in marking and coding, which is essential for regulatory compliance, product traceability, and safety, comes with its own set of challenges. This requires specialized solutions, particularly in the realm of Continuous Inkjet (CIJ) technology. With over 45 years of experience, Hitachi has developed advanced CIJ printers with specially formulated, CIJ inks that are designed for fast-drying. As your trusted partner for pharmaceutical printing, we ensure not only precision and high quality in marking & coding but also unwavering adherence to regulatory mandates and commitment to patient safety amidst this intricate landscape.

Key Industry Challenges

The sensitivity of tablets & syrups, the stringent standards of cleanroom environments for vaccine formulations, the diversity of surface materials encountered, and the imperative of meeting serialization demands - these hurdles for marking and coding for pharmaceutical and medical device products are indeed multifaceted.

Enhancing Precision in Product Identification & Traceability

A growing need for high-resolution coding solutions to keep pace with rapid production demands

Stringent regulatory requirements in the pharmaceutical domain mandate precise product identification and traceability, necessitating the adoption of clear and sharp codes such as GS1 standards. Addressing this need for clean, high-speed coding, Hitachi introduces game-changing industrial printing equipment - the UX2-Dynamic CIJ printer. This cutting-edge printer boasts an innovative dot control algorithm, ensuring superior print quality, and enabling pharmaceutical manufacturers to maintain accuracy and compliance while meeting the demands of high-speed production.

Battling Counterfeit Drugs

The need for a coding solution to add an additional layer of protection

Counterfeit drugs pose a significant threat to public health, underscoring the critical need for robust security measures within the pharmaceutical sector. Invisible UV fluorescent inks emerge as a potent defense. These inks remain undetectable under standard lighting conditions but reveal themselves under UV light, thwarting counterfeiters and tampering attempts. Hitachi spearheads this security initiative by incorporating Invisible UV Fluorescent inks into their state-of-the-art marking & coding solutions, fortifying pharmaceutical product integrity and safety against illicit activities.

Strengthening Supply Chain Pharmaceutical Serialization

Accuracy of code verification is a prerequisite for meeting stringent regulatory standards

Serialization and track-and-trace capabilities are non-negotiable in today's pharmaceutical landscape, serving as pillars of product authentication and supply chain security. Hitachi's MC-20 Vision system emerges as a frontrunner in this arena, featuring Optical Character Verification (OCV) technology tailored specifically for Continuous Inkjet matrix printing. Equipped with conditional grading, this system meticulously scrutinizes each character in a dot matrix, promptly flagging any deviations or rejected prints. With Hitachi's OCV solutions, pharmaceutical companies can uphold regulatory compliance, ensuring the accuracy of their coding and safeguarding product integrity throughout the supply chain.

High-Speed Printing in Confined Spaces

Coding solution must strike a balance between speed and precision

In environments where speed is of the essence and space is limited, pharmaceutical manufacturers face a unique challenge. With small packaging and high-speed production lines, printers must deliver clear and precise markings without compromising quality. Hitachi's UX-Ultra High-Speed Printers are engineered to meet these demands, accommodating small print areas and offering options for colored pigmented inks like white and yellow in addition to black dye inks. Maintaining code clarity, even with short heights of 1-4 mm, this printer empowers manufacturers to meet the demands of high-speed production without compromising on readability or quality.

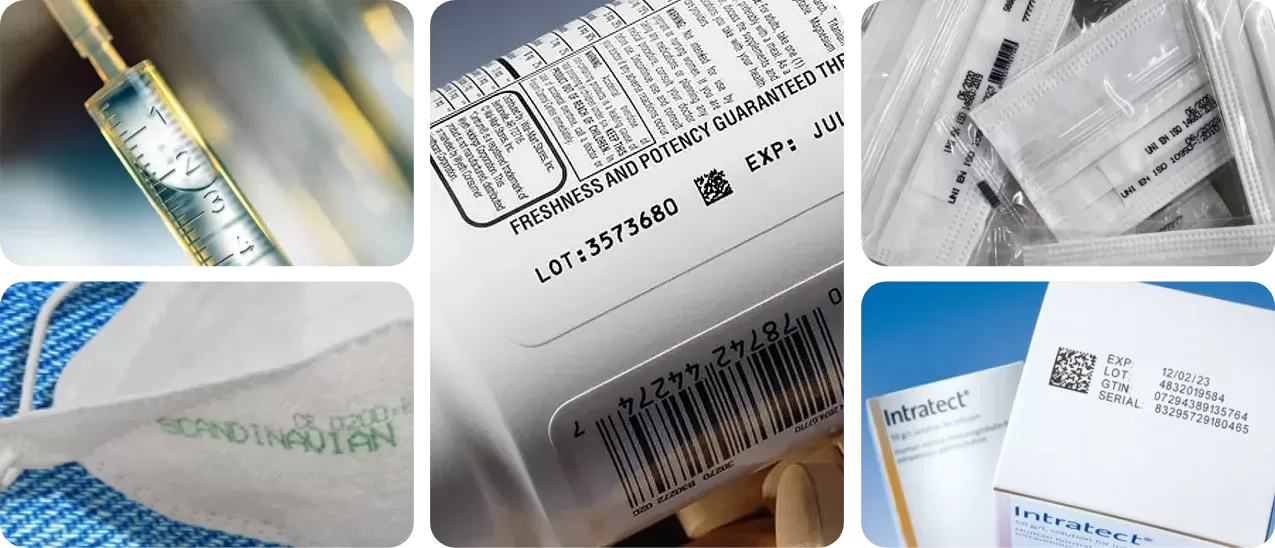

Common Printing & Packaging Applications

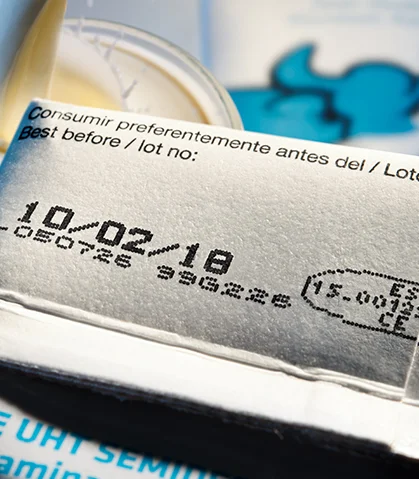

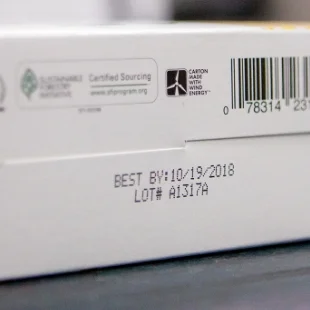

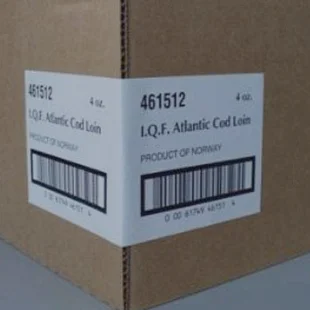

From printing on blister packs and implants to the intricate textures of vials, convey essential information such as dosage instructions, expiration dates, and batch numbers through legible and durable codes, driving patient safety and regulatory compliance.

Helpful Resources

Browse through Hitachi's insightful resources, including product videos, brochures, and inspiring customer success stories to stay informed on the best practices and latest advancements in pharmaceutical and medical marking & coding technology.

Why Choose Hitachi CIJ Printers

With an illustrious history of over four decades in industrial equipment and solutions, Hitachi is your esteemed partner for precision marking and coding solutions. Our unwavering commitment to quality, safety, and sustainability underpins the reliability of Hitachi Continuous Inkjet (CIJ) printers for variable data printing and other industry-specific marking and coding requirements. Fueled by advanced technology and continuous innovation, we offer unmatched customer support to help you boost production uptime and achieve operational excellence.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

Dairy

Dairy  Construction

Construction  Automotive

Automotive  Meat & Seafood

Meat & Seafood  Cosmetic

Cosmetic  Bakery

Bakery  Candy & Confectionary

Candy & Confectionary  Canning (Foods)

Canning (Foods)  Beverage

Beverage  Egg

Egg  Electronics

Electronics  Tobacco & Cannabis

Tobacco & Cannabis  Wire & Cable

Wire & Cable

English

English

Portuguese

Portuguese

Spanish

Spanish