Looking for industrial labeling solutions? Whether you need semi-automatic labels for your secondary packaging or a fully integrated system, we have got you covered. We offer a range of labeling machines, from low-volume tabletop labeling machines, to label, print & apply label applicators, to high-volume zero downtime systems, all designed and manufactured for durability and high performance.

From round product labeling, front & back labeling, carton labeling, or any custom labeling application, our industrial labeling systems are a cost-friendly option when printing shipping information, including barcodes for shipment tracking. Compact and efficient, our semi-automatic labeler machines seamlessly integrate into your production line, optimizing efficiency just before product shipping.

Templates can be locked to reduce manual errors

Allows more responsive layout with a clearly defined print area

Labeler and applicator can be integrated into several ways, depending on production line foot-print

Printing on a single substrate reduces smear or fading issues

Get to know our feature-rich industrial labeling machines.

Label Applicators

Provided by Hitachi Preferred Supplier

-

Single or front & back labeling

Single or front & back labeling

-

Adjustable product carriage .375”-

Adjustable product carriage .375”-

-

6” diameter (9.525 mm – 152.4 mm)

6” diameter (9.525 mm – 152.4 mm)

-

Photoelectric label sensorm)

Photoelectric label sensorm)

-

“Roaming peeler”

“Roaming peeler”

-

6.75” wide web capacity (171.45 mm)

6.75” wide web capacity (171.45 mm)

-

625” minimum label length required (15.875 mm)

625” minimum label length required (15.875 mm)

-

12” (304.8 mm) diameter label supply, 3” (76.2 mm) core

12” (304.8 mm) diameter label supply, 3” (76.2 mm) core

-

Product counter

Product counter

-

Dimensions: 19.41″W x 28.10″L x 27.45″H

Dimensions: 19.41″W x 28.10″L x 27.45″H

-

Product sizes: .5″ to 6″ diameters.

Product sizes: .5″ to 6″ diameters.

-

Web width: up to 6.75″

Web width: up to 6.75″

-

Air: 20 psi minimum.

Air: 20 psi minimum.

-

Weight: 55 lbs.

Weight: 55 lbs.

-

Electric: 120 VAC

Electric: 120 VAC

-

Tamp dwell control

Tamp dwell control

-

“Quick change” tamp heads

“Quick change” tamp heads

-

Dimensions: 19″W x 21″D x 24.75″H.

Dimensions: 19″W x 21″D x 24.75″H.

-

Label roll capacity: up to 12” (304.8 mm) , 3” (76.2 mm) core

Label roll capacity: up to 12” (304.8 mm) , 3” (76.2 mm) core

-

Air: 40PSI Tamp/80PSI Blow-on, electric: 120 VAC

Air: 40PSI Tamp/80PSI Blow-on, electric: 120 VAC

-

Label dispense speed up to 600 ipm (15240 mm)

Label dispense speed up to 600 ipm (15240 mm)

-

Photoelectric label sensor

Photoelectric label sensor

-

6.5” wide web capacity (165.1 mm)

6.5” wide web capacity (165.1 mm)

-

Product detection delay (ON delay)

Product detection delay (ON delay)

-

Label stop delay (OFF delay)

Label stop delay (OFF delay)

Specialty Features

Stepper driven

Stepper-driven technology enhances labeling precision by allowing incremental and precise movements of the labeling mechanism. This fine control ensures accurate placement of labels on various products, optimizing production efficiency and minimizing errors in labeling processes.

Stepper driven

Stepper driven

Stepper-driven technology enhances labeling precision by allowing incremental and precise movements of the labeling mechanism. This fine control ensures accurate placement of labels on various products, optimizing production efficiency and minimizing errors in labeling processes.

Programmable Logic Controller (PLC)

Programmable Logic Controller (PLC) technology empowers our machines with advanced programmability, enabling precise control and customization of labeling processes. PLCs facilitate seamless integration into automated production lines, ensuring consistent and efficient operation while accommodating diverse labeling requirements with ease.

Programmable Logic Controller (PLC)

Programmable Logic Controller (PLC)

Programmable Logic Controller (PLC) technology empowers our machines with advanced programmability, enabling precise control and customization of labeling processes. PLCs facilitate seamless integration into automated production lines, ensuring consistent and efficient operation while accommodating diverse labeling requirements with ease.

Touch Screen Operator Interface

With clear and accessible controls on a modern touch screen display, operators can easily set up, monitor, and adjust labeling parameters with precision. This intuitive interface enhances usability, simplifies training requirements, and promotes efficient operation across different labeling applications.

Touch Screen Operator Interface

Touch Screen Operator Interface

With clear and accessible controls on a modern touch screen display, operators can easily set up, monitor, and adjust labeling parameters with precision. This intuitive interface enhances usability, simplifies training requirements, and promotes efficient operation across different labeling applications.

Foot switch activation

Convenient foot switch activation allows operators to initiate labeling processes hands-free by simply pressing a foot pedal, optimizing workflow efficiency and ensuring precise control during labeling operations.

Foot switch activation

Foot switch activation

Convenient foot switch activation allows operators to initiate labeling processes hands-free by simply pressing a foot pedal, optimizing workflow efficiency and ensuring precise control during labeling operations.

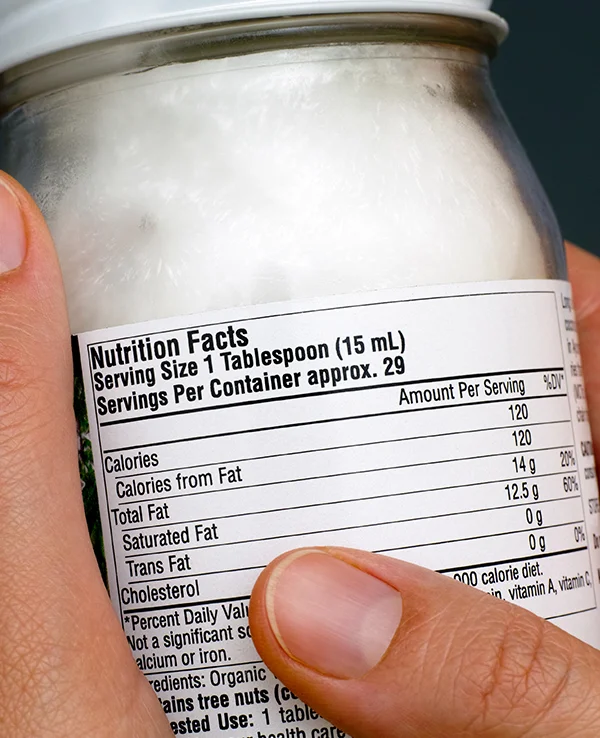

Common Printing & Packaging Applications

Whether it's carton coding on corrugated boxes, barcodes on wood, batch codes on chipboard, or expiry dates on glossy labels, our industrial thermal inkjet printers excel in variable data printing across various substrates and materials that are used in primary and secondary packaging.

Labeling Systems by Industries

Discover the unmatched capabilities of our labeling systems, across a broad spectrum of industries.

Helpful Resources

Put your packaging operations on the fast track with our feature-rich industrial labeling machines. Explore our extensive collection of resources, offering informative product videos, detailed brochures, technical specifications and data sheets, and inspiring customer success stories.

Speak to Our Experts

Call our Toll-Free number for expert guidance on choosing the best marking and coding equipment to meet your diverse industrial printing & packaging application needs.

Get in Touch

Hitachi Industrial Equipment & Solutions America (HIESA) has sales offices strategically located in the Midwest and West Coast regions that specializes in providing primary and secondary packaging equipment and solutions. Beyond our immediate vicinity, we have a wide network of authorized sales partners that we work closely with to ensure that our packaging solutions are accessible to a broader customer base across the Americas and Canada.

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

English

English