Freshness, hygiene, high-speed production lines, and strict adherence to regulations - meat and seafood can be a demanding industry, especially at a time when consumer preferences are constantly changing and food safety is under strict scrutiny. Supply chain traceability plays a critical role in this industry. With Hitachi as your partner, you can rely on our advanced industrial printing technologies and specialized thermochromic inks for marking and coding meat and seafood packaging and outer cartons to achieve the highest standards of print quality and compliance.

Key Industry Challenges

Where food safety, traceability, and regulatory requirements demand the highest standards of print quality, traditional date coders face challenges in maintaining legible codes on varied surfaces amidst high-speed production and ensuring durability in moisture-laden environments.

Durability to Withstand Washdowns and Cold Temperature

Rigorous cleaning processes and low-temperature environments impact code legibility

In the meat and seafood processing environments, maintaining hygiene standards is crucial, often requiring frequent washdowns with cleaning agents. Traditional printers may falter in these harsh cold conditions, resulting in downtime and maintenance issues. Hitachi’s UX2-Dynamic Continuous Inkjet (CIJ) printer, with an IP65 rating, is specifically engineered to withstand washdowns, can operate at low temperatures, and is built with durable components. Additionally, a variety of inks with low-temperature operating points ensure continuous production without interruptions.

Enhancing Meat Industry Safety

Vapors and odors released during manual printhead cleaning lead to safety concerns

Manual CIJ printhead cleaning processes are labor-intensive, time-consuming, and require special training, leading to downtime and safety concerns for operators and products. Our innovative Safe-Clean Station streamlines the cleaning process, saving operators valuable time by automatically cleaning the printhead once put into the station. No training required. Additionally, our system incorporates air pumps equipped to effectively remove vapors during the cleaning and drying process, preventing the spread of potentially hazardous odors for the safety of both - the operators and products.

Maximizing Print Efficiency on Challenging Surfaces

The solution must adapt to different surface types without compromising code legibility

Canned meat products necessitate extensive labeling, encompassing vital details like batch numbers, expiration dates, ingredients, and nutritional information. Industrial printers play a crucial role in managing and accurately printing this wealth of information while ensuring clarity and legibility. However, in many cases, traditional printers may struggle to accommodate all necessary details. Enter Hitachi's UX-Twin Nozzle CIJ Printer—a revolutionary marking solution tailored for meat and seafood packaging. With its enhanced capabilities, the UX-Twin Nozzle Printer allows prints to hold more information with double the character height, streamlining printing processes and elevating efficiency in canning production.

Ensuring Precise Cooking with Temperature-sensitive Ink Technology

Maintaining consistency in Food Quality, Taste, Texture & Safety

In the canned meat industry, ensuring precise cooking times is crucial for maintaining food safety and product quality. Hitachi has developed thermochromic color changing inks designed to accurately signal the end of the cooking process during retort boil or steam processes. With Hitachi's thermochromic marking solutions, canning manufacturers can enhance their operations by reliably identifying when canned products are finished cooking, ensuring optimal taste, texture, and food safety.

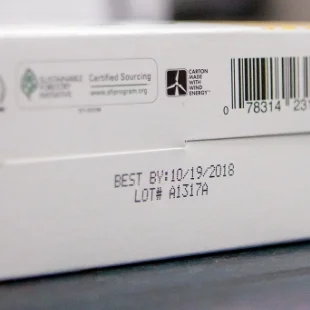

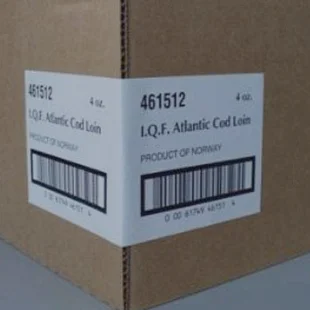

Compliance with Stringent Regulatory Standards

Sophisticated coding systems are needed for accurately capturing product information throughout the supply chain

Hitachi meets these requirements through the MC-20 Vision system, engineered for Continuous Inkjet matrix printing. Featuring Optical Character Verification (OCV) technology, this system meticulously inspects every character within a dot matrix, identifying any deviations and flagging rejected prints based on conditional grading. By providing real-time quality control, the MC-20 Vision System reduces downtime by promptly notifying operators of performance issues, thus ensuring uninterrupted efficiency and productivity.

Common Printing & Packaging Applications

From printing on shrinkwrap and metal cans to food vacuum packs, achieve precise printing and convey crucial information including expiry dates, batch numbers, and product origins reliably with Hitachi, ensuring consumer safety and regulatory compliance throughout the distribution chain.

Helpful Resources

Browse through Hitachi's insightful resources, including product videos, brochures, and inspiring customer success stories from the food industry especially curated to support you in maximizing the efficiency and effectiveness of your marking and coding processes.

Why Choose Hitachi CIJ Printers

With an illustrious history of over four decades in industrial equipment and solutions, Hitachi is your esteemed partner for precision marking and coding solutions. Our unwavering commitment to quality, safety, and sustainability underpins the reliability of Hitachi Continuous Inkjet (CIJ) printers for variable data printing and other industry-specific marking and coding requirements. Fueled by advanced technology and continuous innovation, we offer unmatched customer support to help you boost production uptime and achieve operational excellence.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

Dairy

Dairy  Construction

Construction  Automotive

Automotive  Cosmetic

Cosmetic  Bakery

Bakery  Candy & Confectionary

Candy & Confectionary  Canning (Foods)

Canning (Foods)  Beverage

Beverage  Egg

Egg  Electronics

Electronics  Tobacco & Cannabis

Tobacco & Cannabis  Wire & Cable

Wire & Cable  Pharmaceutical & Medical

Pharmaceutical & Medical

English

English

Portuguese

Portuguese

Spanish

Spanish