Navigating the demanding beverage industry’s printing challenges requires innovative marking & coding solutions that withstand high-speed production lines and moisture-prone environments. Hitachi steps into this dynamic area as a driver of technological innovation and reliability, offering a wide range of solutions for marking and coding beverage containers & packaging materials. With every accurate code on a wine bottle or juice can, Hitachi reinforces the bond between brands and consumers, building trust, enhancing customer retention, and nurturing brand loyalty.

Key Industry Challenges

In the upbeat beverage industry, here high-speed production and condensation challenges prevail, every minute counts and every detail matters.

Efficiency in Motion: Keeping Pace with the High-Speed Production Lines

High-speed printing solutions to avoid disruptions in the production flow

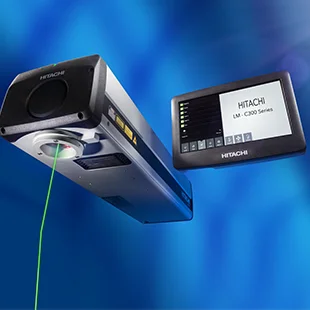

Beverage production lines often operate at incredibly high speeds, with the ability to fill thousands of bottles per hour to meet the increasing consumer demand. Marking and coding equipment must be capable of keeping up with the pace without compromising on quality or productivity. With its superior performance and a print rate of more than 3,000 characters per second, the UX-High Speed CIJ Printer effortlessly keeps pace with fast-moving production lines, delivering reliable and efficient printing solutions.

Overcoming Downtime in Washdown Environments

Traditional printers may struggle to withstand the rigors, leading to increased downtime for maintenance and repairs

In industries like beverages, where equipment must undergo frequent washdowns and exposure to cleaning agents to maintain cleanliness and hygiene standards, downtime becomes a significant concern. Hitachi addresses these concerns with the UX2-Dynamic CIJ Printer, specially designed to withstand washdowns and built with durable components. Furthermore, our patented Ink Guard technology extends the time between printhead cleanings, ensuring uninterrupted production and maximum efficiency for beverage manufacturers.

Streamlining Code Management in Beverage Production

Reducing manual coding adjustment errors to save time and costs

To efficiently manage changing product codes on a beverage production line poses a significant challenge for producers. The manual change of codes on multiple printers is not only time-consuming but also disrupts production flow and heightens the risk of errors. To address these concerns, Hitachi presents the Hitachi Coding Software Suite (HCSS). This innovative printing automation software empowers users to send multiple print codes from one or more computers or devices, while also providing real-time monitoring of all Hitachi CIJ printers. With HCSS, beverage producers can streamline their code management process, enhancing efficiency and minimizing the risk of errors along the production line.

Alkaline Washability

Coding solutions must ensure clear and easily removable markings to maintain hygiene and packaging integrity

In beverage manufacturing, ensuring cleanliness and hygiene standards is of utmost importance, particularly returnable items are subject to rigorous washes with alkaline based solutions. The ability to easily remove markings from these items after exposure to such wash solutions is essential. Hitachi provides specialized inks precisely tailored for this purpose, effectively removing marks without leaving residue or damage to the packaging material during the washing process.

Navigating Product Code’s Environment Challenges

Ensuring that ink withstands changes in environments is a critical concern for beverage manufacturers

As beverages traverse diverse environments from production to consumption, maintaining clear and durable markings becomes essential. This is especially important for high-condensation environments or dealing with products that may be chilled, dried or exposed to moisture during processing, shipping, and storage. Hitachi offers a comprehensive range of ink solutions meticulously formulated to withstand the varying conditions encountered throughout the beverage supply chain process by mitigating the risks of smudged or illegible codes. Hitachi's ink formulations & solutions further enhance operational efficiency and maintain compliance with regulatory standards.

Enhancing Beverage Industry Efficiency & Productivity

Robust beverage coding systems are needed for accurate and reliable information throughout the supply chain

In the fast-paced world of the beverage industry, maintaining accuracy and print quality on high-speed production lines is essential, especially when dealing with large quantities of products. To meet these challenges head-on, Hitachi has developed the MC-20 Vision system. Specifically designed for continuous inkjet matrix printing, this system features Optical Character Verification (OCV) technology. It meticulously examines each character in a dot matrix, flagging any deviations and rejecting prints with the use of conditional grading. By providing real-time quality control, the MC-20 Vision system minimizes downtime by alerting operators to performance issues, ensuring continuous efficiency and productivity.

Common Printing & Packaging Applications

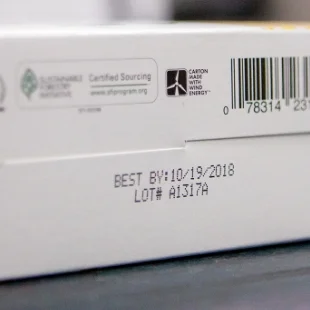

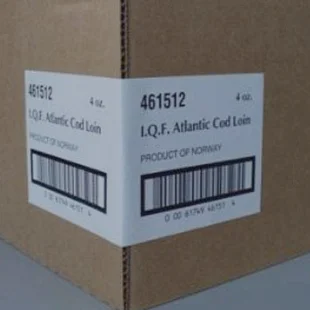

From marking & coding on glass and PET bottles to metal cans or carton boxes, Hitachi’s variable data printing solutions cater to every beverage packaging type with precision and reliability. Print batch numbers, best-before date, barcodes, data matrix codes, or serial numbers with ease and high accuracy.

Helpful Resources

In a world of high-speed lines and demanding manufacturing conditions, Hitachi's industrial marking & coding expertise ensures seamless operations and unparalleled reliability in the beverage sector. Explore our collection of informative product videos, downloadable industry guides, and inspiring customer success stories from the Beverage industry.

Why Choose Hitachi CIJ Printers

With an illustrious history of over four decades in industrial equipment and solutions, Hitachi is your esteemed partner for precision marking and coding solutions. Our unwavering commitment to quality, safety, and sustainability underpins the reliability of Hitachi Continuous Inkjet (CIJ) printers for variable data printing and other industry-specific marking and coding requirements. Fueled by advanced technology and continuous innovation, we offer unmatched customer support to help you boost production uptime and achieve operational excellence.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

Dairy

Dairy  Construction

Construction  Automotive

Automotive  Meat & Seafood

Meat & Seafood  Cosmetic

Cosmetic  Bakery

Bakery  Candy & Confectionary

Candy & Confectionary  Canning (Foods)

Canning (Foods)  Egg

Egg  Electronics

Electronics  Tobacco & Cannabis

Tobacco & Cannabis  Wire & Cable

Wire & Cable  Pharmaceutical & Medical

Pharmaceutical & Medical

English

English

Portuguese

Portuguese

Spanish

Spanish