Packaging systems are a critical component of finishing primary and secondary packaging before shipment. Manufacturers rely on tape sealing and product handling equipment to streamline product transport.

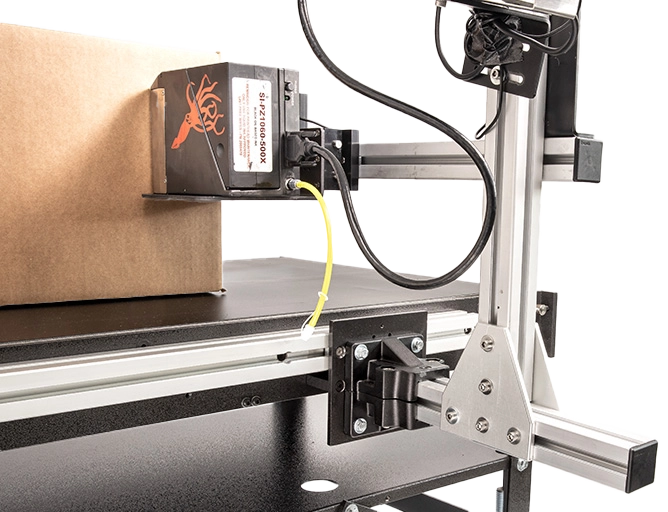

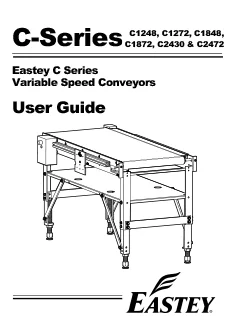

Our tape sealers are perfect for boxes of all sizes and weights, including void-fill cases where the product doesn't fully support the box. Our variable speed conveyors provide dependable, stand-alone product handling and transport, ideal for primary or secondary product marking. They also make an excellent addition as an infeed or exit feed conveyor for existing case-taping or shrink-wrapping equipment.

Product Handling

Primary Features

Such as spare print heads, printer and UV LED control boxes, spare ink, and more

Specialty Features

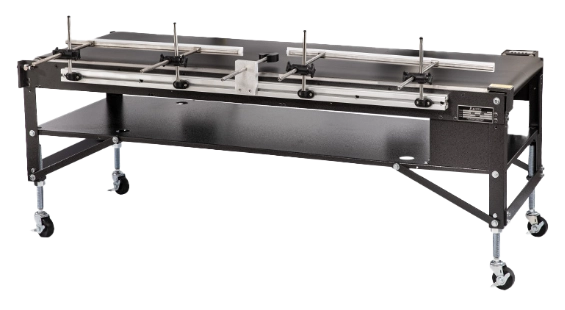

Explore the unique features and benefits of our high-performance product-handling equipment that offers convenient product transport.

Durability

Heavy-duty motor, industrial strength drive belt, and a simple design with each conveyor made from ¼” steel that withstands even the most rugged applications.

Durability

Durability

Heavy-duty motor, industrial strength drive belt, and a simple design with each conveyor made from ¼” steel that withstands even the most rugged applications.

Ease of Use

Conveyor legs are adjustable from 20” up to 33.5”.

Ease of Use

Ease of Use

Conveyor legs are adjustable from 20” up to 33.5”.

Seamless self-tracking belt

Our easy-to-use conveyors utilize an endless belt with a self-tracking V-groove for consistent product alignment

Seamless self-tracking belt

Seamless self-tracking belt

Our easy-to-use conveyors utilize an endless belt with a self-tracking V-groove for consistent product alignment

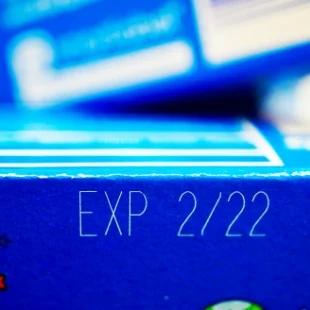

Designed for inkjet applications

Perfect for integration with ink jet printing equipment.

Designed for inkjet applications

Designed for inkjet applications

Perfect for integration with ink jet printing equipment.

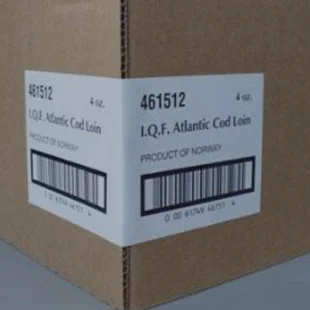

Pre-drilled hole for printer/encoder mounting

Each conveyor comes pre-drilled in multiple locations to easily add printer and encoder mounting brackets

Pre-drilled hole for printer/encoder mounting

Pre-drilled hole for printer/encoder mounting

Each conveyor comes pre-drilled in multiple locations to easily add printer and encoder mounting brackets

Variable speed drive

The variable speed drive motor is adjustable up to 100 fpm for a variety of applications

Variable speed drive

Variable speed drive

The variable speed drive motor is adjustable up to 100 fpm for a variety of applications

Smooth, consistent belt speed

The smooth drive belt provides consistent speed for reliable, scannable barcoding and product transfer.

Smooth, consistent belt speed

Smooth, consistent belt speed

The smooth drive belt provides consistent speed for reliable, scannable barcoding and product transfer.

Safety

Safety cover over pinch points for worker & product safety

Safety

Safety

Safety cover over pinch points for worker & product safety

Low Maintenance

The system is designed to keep maintenance to a minimum and provide a fast and efficient method of product transport.

Low Maintenance

Low Maintenance

The system is designed to keep maintenance to a minimum and provide a fast and efficient method of product transport.

Tape Sealers

Primary Features

Designed for effortless plug-and-go operation, ensuring minimal setup time and maximum efficiency.

Top and bottom tape heads are identical, interchangeable and are designed for easy threading, and can be removed instantly without tools.

Industrial strength roller beds move boxes consistently through the taper.

Fast and easy case changes with adjustable side rails and flexibility for boxes 5” long and greater.

Specialty Features

Explore the unique features and benefits of our tape sealing equipment.

Wide standard case range

Wide standard case range

Wide standard case range

Fast and easy box size changes

Fast and easy box size changes

Fast and easy box size changes

Emergency stop button

Emergency stop button

Emergency stop button

Casters for transportation within the plant

Casters for transportation within the plant

Casters for transportation within the plant

Front and rear pack tables to allow for case packing

Front and rear pack tables to allow for case packing

Front and rear pack tables to allow for case packing

Top squeezers push top flaps together for accurate case sealing

Top squeezers push top flaps together for accurate case sealing

Top squeezers push top flaps together for accurate case sealing

Powder-coated 12 gauge steel

Powder-coated 12 gauge steel

Powder-coated 12 gauge steel

Low maintenance, no air required

Low maintenance, no air required

Low maintenance, no air required

CIJ Printers by Industries

We offer a comprehensive range of packaging solutions to cater to a broad spectrum of industries.

Helpful Resources

Explore our extensive collection of resources, offering informative product videos, detailed brochures, technical specifications and data sheets, and inspiring customer success stories to experience the versatility of our packaging equipment.

Speak to Our Experts

Call our Toll-Free number for expert guidance on choosing the best marking and coding equipment to meet your diverse industrial printing & packaging application needs.

Get in Touch

Hitachi Industrial Equipment & Solutions America (HIESA) has sales offices strategically located in the Midwest and West Coast regions that specializes in providing primary and secondary packaging equipment and solutions. Beyond our immediate vicinity, we have a wide network of authorized sales partners that we work closely with to ensure that our packaging solutions are accessible to a broader customer base across the Americas and Canada.

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

English

English