In the dairy industry, producers face several unique challenges such as cold, wet environments and short shelf lives of finished products. Any interruption in production jeopardizes this, especially in fast-moving production lines. To cater to these unique challenges, Hitachi has developed products capable of enduring harsh cold, and wet environments without issue.

With a long history of dedication to innovation and sustainability, Hitachi's state-of-the-art marking and coding solutions seamlessly integrate into your processes, allowing your production lines to achieve optimal performance while also reducing your carbon footprint.

Key Industry Challenges

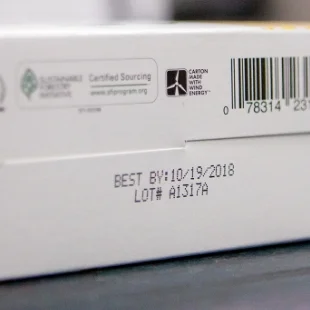

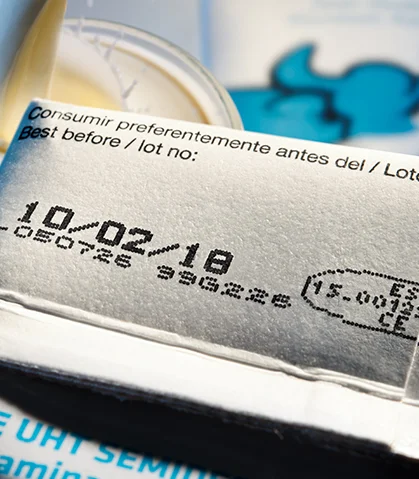

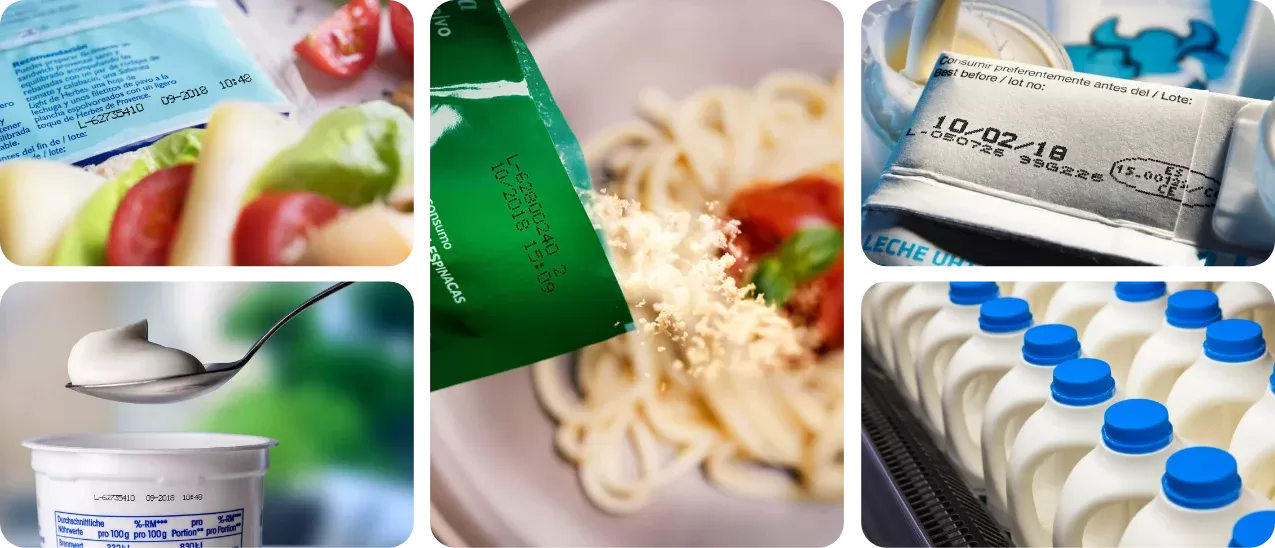

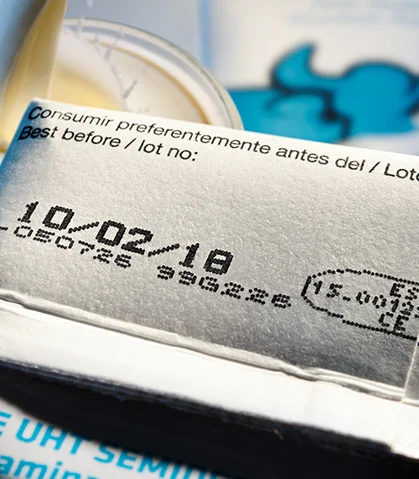

The dairy industry encounters unprecedented challenges, such as managing products with short shelf lives, product traceability, output, cleanliness, and quickly evolving packaging designs which need industrial date coders designed for efficiency and flexibility across different dairy packaging types.

Overcoming Washdown Environments

Ensuring continuous production amid rigorous hygiene standards in dairy manufacturing

In dairy manufacturing environments, maintaining hygiene standards is crucial, often requiring frequent washdowns with cleaning agents. Traditional printers may falter in these harsh conditions, resulting in downtime and maintenance issues. Hitachi's UX2-Dynamic CIJ Printer is specifically engineered with an IP65 rating to withstand washdowns and built with durable components, ensuring continuous production without interruptions. Furthermore, an optional printhead pressurization kit further mitigates issues caused by moisture, ensuring seamless production processes.

Eliminating Odor Impact - By Using Eco-Friendly & Low Odor Inks

Preventing printing ink odor absorption to preserve product quality

Dairy products are highly sensitive to external odors and flavors. If ink or solvent fluids emit strong odors, they may contaminate the flavor of dairy products, leading to off-flavors or unpleasant tastes. Hitachi addresses this concern with eco-friendly, low-odor inks that preserve the taste and aroma of dairy goods. Our printing solutions ensure customer satisfaction by eliminating any risk of tainted flavors, providing dairy businesses with peace of mind, and maintaining the integrity of their products.

Enhancing Safety in the Dairy Industry – For Products and Workforce

Manual CIJ printhead cleaning processes are labor-intensive, time-consuming, and require special safety training, leading to downtime and safety concerns for operators and products. Our Safe-Clean Station streamlines the cleaning process, saving operators valuable time by automatically cleaning the printhead once put into the station. There are multiple cleaning mode options available on every printer and no special training is required. Additionally, our system incorporates air pumps equipped to effectively remove vapors during the cleaning and drying process, preventing the spread of potentially hazardous odors for both the operators and products.

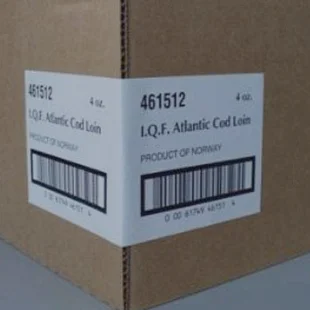

Common Printing & Packaging Applications

From printing on plastic bottles and cartons to plastic tubs, trays, and glass, avail our precise and reliable coding and marking solutions for a multitude of primary and secondary packaging applications in the dairy industry.

Helpful Resources

With Hitachi, enjoy reduced downtime even in the harshest conditions, higher production line speeds, and lower total cost of ownership, revolutionizing your dairy coding experience. Browse through our product videos, brochures, and customer success stories from the dairy industry to get the most out of our marking and coding solutions and maximize your Return on Investment.

Explore our Marking & Coding Solutions for the Dairy Industry

Baker Cheese Increases Production and Print Quality with the Hitachi RX Series Printers

Why Choose Hitachi CIJ Printers

With an illustrious history of over four decades in industrial equipment and solutions, Hitachi is your esteemed partner for precision marking and coding solutions. Our unwavering commitment to quality, safety, and sustainability underpins the reliability of Hitachi Continuous Inkjet (CIJ) printers for variable data printing and other industry-specific marking and coding requirements. Fueled by advanced technology and continuous innovation, we offer unmatched customer support to help you boost production uptime and achieve operational excellence.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

Construction

Construction  Automotive

Automotive  Meat & Seafood

Meat & Seafood  Cosmetic

Cosmetic  Bakery

Bakery  Candy & Confectionary

Candy & Confectionary  Canning (Foods)

Canning (Foods)  Beverage

Beverage  Egg

Egg  Electronics

Electronics  Tobacco & Cannabis

Tobacco & Cannabis  Wire & Cable

Wire & Cable  Pharmaceutical & Medical

Pharmaceutical & Medical

English

English

Portuguese

Portuguese

Spanish

Spanish