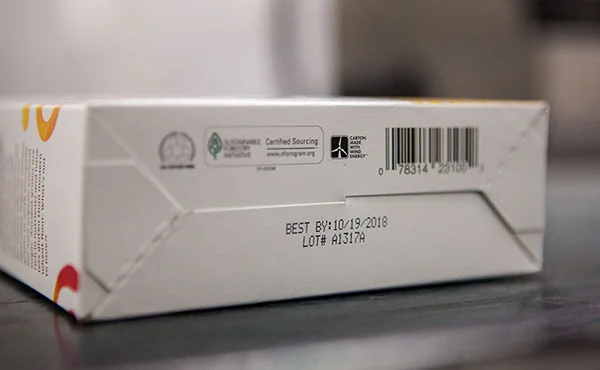

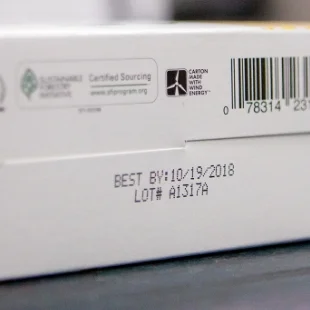

As the demand for canned foods continues to rise, so does the need for stringent food safety and traceability measures. Hitachi's state-of-the-art marking and coding solutions for the food industry uphold the highest quality and compliance standards, ensuring that every food can is marked with clear, durable codes, despite the challenges of high-speed production & fluctuating temperatures.

Key Industry Challenges

Canning lines frequently operate at high speeds to meet production demands, necessitating date coders that must operate at high speeds while maintaining the accuracy and clarity of the markings. It is important to find a solution that will seamlessly integrate into your production line.

Achieving High-Speed Printing on Food Cans

Printers must match the rapid pace while upholding accuracy, quality & operational efficiency

Canning facilities operate at high speeds to keep up with demand. Furthermore, seasonal produce has a limited harvesting window, placing pressure on canning facilities to process and package products quickly. Industrial CIJ printers must match this pace while maintaining accuracy and quality, without compromising on efficiency, avoiding bottlenecks, and keeping pace of schedules. Hitachi has created a solution that can match those speeds through the UX-High Speed CIJ Printer. The UX-High Speed Printer outperforms standard printers on high-speed production lines without compromising print quality.

Maximizing Print Efficiency

Canning food products demands a robust printer for meticulous labeling

Canning food products necessitates extensive labeling, encompassing vital details like batch numbers, expiration dates, ingredients, and nutritional information. Traditional printers often falter in accommodating this breadth of information, risking clarity and legibility. Enter Hitachi's UX-Twin Nozzle CIJ Printer—a revolutionary solution tailored for the canning industry. With its enhanced capabilities, the UX-Twin Nozzle Printer allows prints to hold more information with double the character height, streamlining printing processes and elevating efficiency in canning production.

Overcoming Seasonal Packaging Challenges

In the canning industry, seasonal fluctuations pose printing hurdles

In the canning industry, seasonal produce presents a unique challenge: printers often remain inactive during off-seasons, leading to difficulties in restarting operations when the season resumes. Hitachi offers a solution with the Safe-Clean Station. More than just a CIJ print head cleaning machine, the Safe-Clean Station can recirculate ink once per day, up to once per week, ensuring the printers are ready after an off season. This will reduce the maintenance needed to start up the printer after a long shutdown resulting in streamlined operations and maximized efficiency in the canning industry.

Meeting the Demand for Accurate Cooking Timings in Canning Operations

Precise cooking timings are paramount for upholding food safety and quality standards

In the canning industry, ensuring precise cooking times is crucial for maintaining food safety and product quality. Hitachi has developed thermochromic color changing inks designed specifically for cans, accurately signaling the end of the cooking process during retort boil or steam processes. With Hitachi's thermochromic marking solutions, canning manufacturers can enhance their operations by reliably identifying when canned products are finished cooking, ensuring optimal taste, texture, and food safety.

Overcoming Washdown Environments

Ensuring continuous production amid rigorous hygiene standards in food manufacturing

Food manufacturing facilities often require frequent washdowns to maintain cleanliness and hygiene standards. Markings on food cans must withstand these challenges to maintain legibility throughout the product's lifecycle. Moreover, stringent washdown protocols necessitate printers resistant to water ingress. Traditional printers may falter in these harsh conditions, resulting in downtime and maintenance issues. Hitachi addresses this need with the UX2 Dynamic CIJ Printer. IP65-rated, its robust construction ensures resilience against environmental factors, including washdown procedures, ensuring continuous production without interruptions. Additionally, an optional printhead pressurization kit further mitigates issues caused by moisture, ensuring seamless production processes.

Enhancing Canning Industry Efficiency

Maintaining accuracy and print quality in high-speed canning

In the fast-paced world of the canning industry, maintaining accuracy and print quality on high-speed production lines is essential, especially when dealing with large quantities of products. To meet these challenges head-on, Hitachi has developed the MC-20 Vision system. Specifically designed for Continuous Inkjet matrix printing, this system features Optical Character Verification (OCV) technology. It meticulously examines each character in a dot matrix, flagging any deviations, and rejects prints with the use of conditional grading. By providing real-time quality control, the MC-20 Vision system minimizes downtime by alerting operators to performance issues, ensuring continuous efficiency and productivity.

Common Printing & Packaging Applications

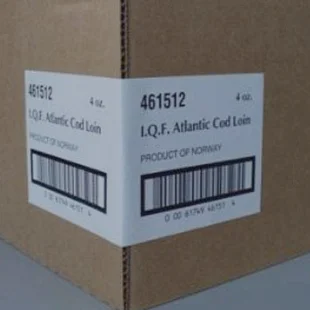

Leverage our distinctive marking & coding equipment capable of producing high-resolution printing of labels, barcodes, logos, and product information directly onto food cans to meet regulatory compliance for traceability and consumer safety.

Helpful Resources

In a market driven by taste and trust, Hitachi remains the go-to choice for canning (foods) industry businesses seeking reliability and innovation in their packaging operations. Explore our collection of informative product videos, downloadable industry guides, and inspiring customer success stories from this industry.

Why Choose Hitachi CIJ Printers

With an illustrious history of over four decades in industrial equipment and solutions, Hitachi is your esteemed partner for precision marking and coding solutions. Our unwavering commitment to quality, safety, and sustainability underpins the reliability of Hitachi Continuous Inkjet (CIJ) printers for variable data printing and other industry-specific marking and coding requirements. Fueled by advanced technology and continuous innovation, we offer unmatched customer support to help you boost production uptime and achieve operational excellence.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

Dairy

Dairy  Construction

Construction  Automotive

Automotive  Meat & Seafood

Meat & Seafood  Cosmetic

Cosmetic  Bakery

Bakery  Candy & Confectionary

Candy & Confectionary  Beverage

Beverage  Egg

Egg  Electronics

Electronics  Tobacco & Cannabis

Tobacco & Cannabis  Wire & Cable

Wire & Cable  Pharmaceutical & Medical

Pharmaceutical & Medical

English

English

Portuguese

Portuguese

Spanish

Spanish