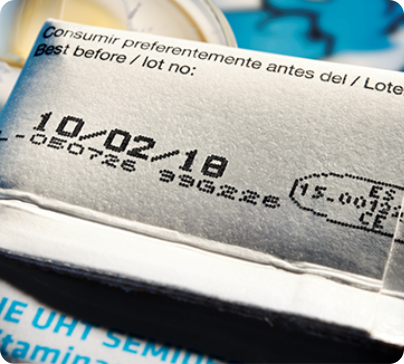

At Hitachi, we prioritize the research and development of innovative new ink technology for our continuous inkjet printers. Our high-quality inks and solvents are designed to maximize ink efficiency, ensure consistent and legible codes while minimizing wear and tear Hitachi continuous inkjet printers, resulting in more uptime for your production.

Our advanced ink research and development focuses on improving adhesion to various substrates under challenging production conditions by developing specialty inks. Our inks are designed for our patented smart cartridge systems that make fluid refills error-free and reduce ink and solvent waste in cartridge containers. Additionally, our CIJ fluids comply with ever-changing global health and safety standards.

General Purpose Inks

General Purpose Inks

At Hitachi, we have engineered a comprehensive selection of general-purpose inks for continuous inkjet printers that address the multifaceted needs of diverse industries and applications. Our lineup encompasses a variety of formulations meticulously engineered to deliver superior performance and reliability across the board.

Geneal-Purpose Dye-based Inks

Experience high-grade inks that have a long shelf like, and produce crisp, legible prints all while ensuring stable printer operation.

General-Purpose Carbon-based Inks

Achieve durable and resilient codes, with resistance to retort processes and or fading from sunlight, making them ideal for demanding environments.

General-Purpose Acetone-based Inks

Benefit from rapid drying times and minimal odor emissions, perfect for high-speed operations where efficiency is key.

General-Purpose High-Performing Inks

Our top-tier general-purpose inks ensure superior adhesion and consistent quality codes, meeting the exacting standards of modern manufacturing with unwavering reliability and efficiency.

Fast-Drying Inks

Fast-Drying Inks

Fast-drying inks represent a pivotal solution for rapid production environments, characterized by its acetone-based formulation capable of drying in under a single second. This swift drying time is especially advantageous for continuous high-speed manufacturing lines, such as flow wrappers, where efficiency and throughput are paramount.

Rapid Drying

Achieve rapid drying times, enhancing throughput, and preventing smudging compared to slower drying inks.

Odorless Formulation

Unlike traditional MEK inks, our fast-drying inks also ensure minimal odor, crucial for industries sensitive to odor contamination which can lead to undesirable taste profiles.

Unrivaled Efficiency

With Hitachi's fast-drying inks, manufacturers can maintain peak productivity without compromising product quality.

Eco-Friendly Inks

Eco-Friendly Inks

Hitachi's Eco-Friendly Inks, a revolutionary step towards sustainable printing practices. Crafted from environmentally responsible materials and processes, these inks offer a greener alternative to traditional formulations. By embracing environment-friendly ink solutions, manufacturers not only fulfill their environmental responsibilities but also enhance product quality and reduce operational expenses.

MEK-Free Formulations

Unlike traditional ink formulations, which often rely on volatile compounds like MEK or Acetone, eco-friendly inks offer good adhesion while being environmentally friendly.

Odor Contamination Prevention

Unlike traditional MEK inks, eco-friendly inks eliminate the risk of odor contamination to products which can lead to undesirable taste profiles such as chocolates, confections and breads.

Reduced Solvent Consumption

Hitachi's Eco-Friendly have lower evaporation and consumption rates which leads to lower total fluid costs over time, contributing to cost savings.

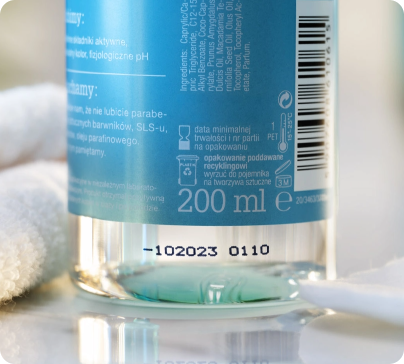

Alcohol Resistant Inks

Alcohol Resistant Inks

Hitachi's Ethanol Resistant Inks are engineered to withstand the challenges of electronic component production lines and cosmetics products. Our alcohol-resistant inks are specifically formulated to resist the effects of ethanol-based washes and exposure to alcohol-based fluids, these inks ensure the longevity and clarity of printed codes.

Manufacturing Durability

Designed to withstand the rigors of manufacturing processes, our ethanol-resistant inks maintain their integrity on electronic components and cosmetic packaging.

Endurance Against Ethanol

Withstand ethanol washes and regular use of products containing ethanol, ensuring printed codes remain clear and legible over time.

Prevent Smudging

Prevents smudging or illegible codes that could compromise product identification, enhancing product traceability and reliability.

Pigmented Inks

Pigmented Inks

Hitachi's Pigmented Inks is the ultimate colored ink solution for printing on dark surfaces with precision and clarity. Crafted to address the unique challenges posed by dark-colored items, our pigmented inks ensure exceptional contrast, visibility, and durability, even under heavy light exposure and environments.

Exceptional Contrast

These high-contrast inks achieve clear and legible codes with exceptional contrast against dark backgrounds, enhancing product identification and traceability.

Long-lasting Resistance

Our pigmented inks offer resistance to heavy light and environmental exposure, ensuring the longevity and reliability of printed codes over time.

Wide Color Selection

Choose from a variety of colors, including yellow, orange, white, blue, and more, to meet diverse printing needs across various surfaces and applications.

Tailored Performance

Our pigmented inks encompass both soft and hard pigment formulations, strategically designed to optimize performance on specific substrates, ensuring consistent and reliable results.

Thermochromic Inks

Thermochromic Inks

Hitachi's Thermochromic Inks (color-changing inks) are engineered to assess heat sterilization processes such as retort boiling or steaming. These specialized inks undergo a color transformation, shifting from black to blue or burgundy to red when exposed to water at specific temperatures and durations.

Heat Sterilization Assessment

Monitor heat sterilization processes, ensuring products meet stringent safety standards.

Color Transition Indicator

Observe a clear color change from black to blue or burgundy to red, signaling the completion of sterilization at the specified temperature and duration.

Versatile Application

Suitable for a wide range of containers, including cans, retort pouches, plastic trays, and more, facilitating seamless integration into various manufacturing processes.

How does the Ink change color?

This ink changes the color of printed ink dots when exposed to the retort process (boil or steam). The color change is achieved when the dried ink dots come in contact with steam or boiling water. Sufficient water is required for changing color.

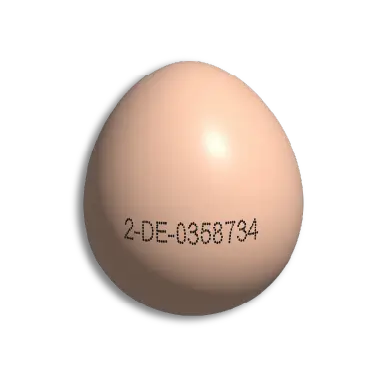

Eggshell Inks

Eggshell Inks

Hitachi's Eggshell Inks, setting the industry standard for precision printing on eggshells. Engineered to adhere seamlessly to the surface of eggshells, our innovative formulations meet stringent Good Manufacturing Practices (GMP) and global regulatory standards for unprocessed eggshells.

Adherence to Global & Regional Standards

Our eggshell inks adhere to strict Good Manufacturing Practices (GMP), ensuring compliance with regional regulations for unprocessed eggshells.

Versatile Formulations

Choose from a variety of formulations tailored to meet specific printing needs, including fast-drying options, condensation resistance, low odor, and exceptional visibility on eggshells.

Clear and Legible Markings

With Hitachi's eggshell inks, achieve clear and legible markings directly on eggshells, enhancing product identification and traceability.

Alkaline Washable Inks

Alkaline Washable Inks

Hitachi's Alkaline Washable Inks, are the versatile solution for marking items that require easy cleaning and restoration to their original state for returnable products. These specialized inks can be efficiently washed off using alkaline solutions, leaving behind a residue-free surface.

Effortless Cleaning

Easily wash off ink markings with alkaline solutions, ensuring a clean and residue-free surface.

Versatile Applications

Suitable for a wide range of items, including glass bottles, metal kegs, and more, providing temporary markings while preserving product integrity for reuse.

Convenient Solution

Hitachi's Alkaline Washable Inks offer a convenient way to mark products temporarily without compromising their quality or usability.

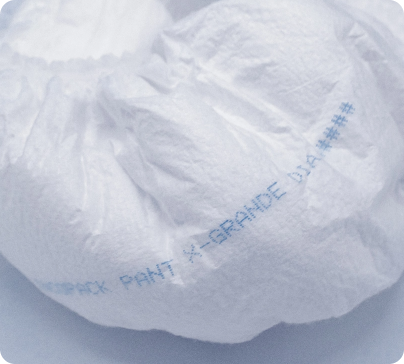

Wetness Indicator Inks

Wetness Indicator Inks

Hitachi's Wetness Indicator Ink is a premium blue ink formulated with pharmaceutical-grade properties for safety and reliability. Engineered to fade upon contact with moisture, this ink provides a clear indicator of wetness or moisture, making it essential for products such as diapers or paper products where monitoring liquid exposure is crucial. Its pharmaceutical-grade composition minimizes the risk of skin contact, ensuring peace of mind for both manufacturers and consumers.

Moisture Indicator

Fades upon contact with moisture, providing a clear indication of wetness for products like diapers or paper.

Pharmaceutical-Grade Safety

Formulated with pharmaceutical-grade properties to minimize the risk of skin contact, ensuring safety and reliability.

Peace of Mind

Offers manufacturers and consumers peace of mind by reliably indicating liquid exposure and maintaining safety standards.

Invisible UV Fluorescent Inks

Invisible UV Fluorescent Inks

Hitachi's Invisible UV Fluorescent Inks, a discreet solution for subtle markings that are only visible under UV lighting. Designed to maintain printed codes invisible to consumers, these innovative inks enhance the product's aesthetic appeal while providing manufacturers with authentication visibility.

Discreet Markings

Achieve subtle markings that are only visible under specific UV lighting, ensuring product aesthetics remain uncompromised.

Authentication Visibility

Unlike conventional inks, Hitachi's fluorescent ink provides manufacturers with UV visibility for authentication purposes, deterring potential counterfeiting threats.

Heat Sterilization Resilience

The UV ink's invisibility persists even after undergoing heat sterilization processes such as retort boiling or steaming, ensuring code integrity and reliability.

Heat Resistant Inks

Heat Resistant Inks

Hitachi's Heat Resistant Inks, the ultimate solution for creating permanent markings that withstand extreme temperatures with exceptional adhesion and durability. These specialized inks provide manufacturers with a reliable solution for permanent markings in applications requiring heat curing or undergoing rigorous heat-sterilization processes.

Exceptional Adhesion

These inks offer outstanding adhesion to surfaces, ensuring longevity and resilience even under extreme heat.

High-Heat Endurance

Engineered to withstand the highest temperatures, these inks excel in environments reaching up to 600°C or higher.

Strengthens Upon Heating

The unique property of strengthening upon heating fortifies the bond between the ink and the surface, ensuring prints remain intact and vibrant

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program