Customization. Automation. Life-Cycle Support

Programming and Equipment Integrations

Programming and Equipment Integrations

-

Integration Services

Seamlessly connect various components of your production line to facilitate a unified and efficient operational flow. This enables real-time data exchange and streamlined communication between machines and human interfaces.

-

Networking & API development (Application Programming Interface)

Creating scalable, efficient, and flexible software systems that can leverage resources distributed across the internet or private networks. Communication Protocols: Ethernet/IP, Modbus TCP, OPC-UA, Linux, Automation Direct

-

PLC programming & Custom software solutions

Design specialized machine logic so you can take precise control of various tasks executed throughout the manufacturing process in real-time and in harsh environments. From synchronization, positioning, sorting & routing, performance monitoring, safety interlocks, and more.

Supported Programming Software : Ignition, Python, C, C++, C#, SQL, Rockwell Logics, Automation Direct

-

Custom Software Solutions

Enhance the capabilities of your operations with user-friendly custom interfaces for monitoring and control even from the production floor.

Advanced algorithms created for complex decision-making needs such as dynamic scheduling and resource allocation based on real-time production line data.

Incorporate machine learning to collect predictive analytics to forecast potential downtime and maintenance needs.;

Design and Fabrication Engineering

Design and Fabrication Engineering

-

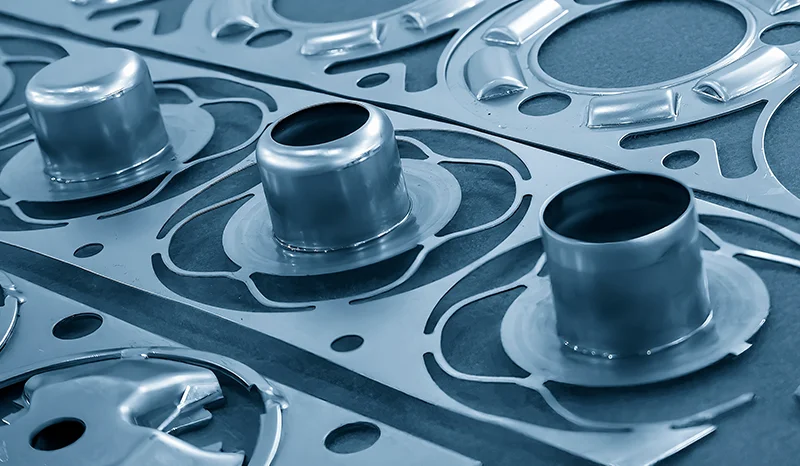

Custom Designs

Personalized solutions that fit the specific requirements of your production environment to ensure every aspect of the machinery and workflow is optimized for your process needs. From bracketry modifications, material selection, safety enclosure fabrication, and more.

-

CAD Drawings

Providing a visualization of your projects before they are built allows for better planning and more accurate installations, reducing the risk of costly errors.

Custom Training and Education Programs (Onsite or Offsite)

Custom Training and Education Programs (Onsite or Offsite)

-

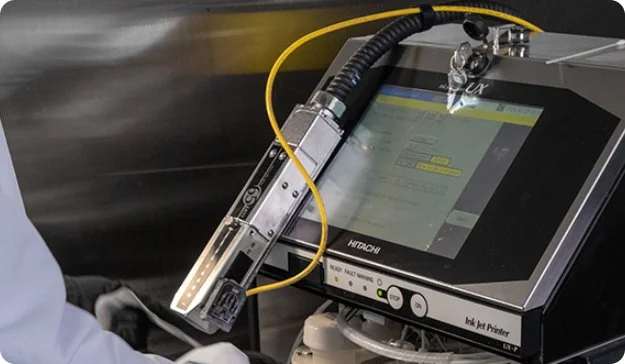

Technical Training

Empower operators with the knowledge, skills, and confidence to operate Hitachi Marking & Coding related equipment correctly. By understanding the intricacies of the equipment, your team can also contribute to process optimization. While also maximizing equipment efficiency and lifespan.

-

Laser Safety Training

Prioritize worker safety – Foster and contribute to a culture of continuous improvement and safety consciousness among your workforce through Hitachi certified training. Create a safer working environment and reduce the risk of workplace accidents or injuries while achieving compliance with industry standards.

Maintenance and Service Support

Maintenance and Service Support

-

Equipment Inspections/Efficiency Review

Conduct thorough inspections of the facility to ensure optimal performance of production line equipment. Receive assessments of the production process and equipment to identify inefficiencies, allowing targeted improvements that enhance productivity and reduce operational costs. Rest assured that your equipment is meeting current industry standards but is also set up for future scalability and improvement.

-

Consultation and Planning

Whether you are in the design phase or already in production, we are here to provide solutions that offer quality, functionality, innovation, and overall efficiency in the manufacturing process.

Geographic Service Coverage

Our extensive network of distributors, resellers & service centers spans every state and country in North and South America.

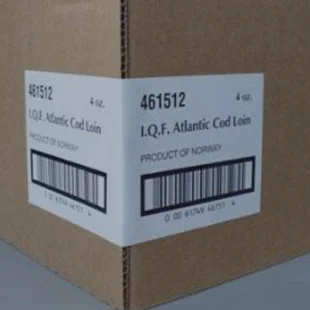

Helpful Resources

Put your production on the fast track with our state-of-the-art marking & coding solutions, customized to suit your production line. Explore our extensive collection of resources, offering informative videos, brochures, and more.

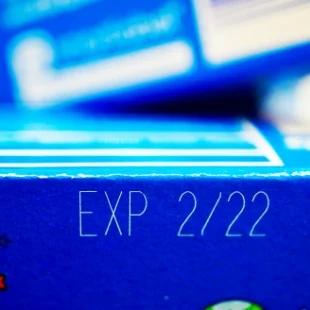

INK & MAKEUP

Dive into the forefront of Continuous Inkjet (CIJ) Ink innovation and discovery as our Ink R&D Center continues to pioneer groundbreaking ink formulations that are customized for diverse applications, delivering high-quality printing solutions aligning perfectly with the demands of multiple industries.

Learn MoreSpeak to Our Experts

Call our Toll-Free number for expert guidance on choosing the best marking and coding equipment to meet your diverse industrial printing & packaging application needs.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

English

English