Ultra-crisp, precision marking on tough materials

Our UV laser marking systems are known for their high absorption rate, which allows them to mark various materials with minimal heat damage and excellent contrast. Our UV laser marking machines feature small but powerful laser beams that enable high-precision micro-marking with exceptional resolution sharpness. The 355 nm UV laser wavelength is versatile in non-contact marking of a wide range of materials and perfect for "cold marking" applications where heat-affected zones are not permitted.

Benefits of UV Laser Marking Machines

Explore specialty features & benefits of our UV lasers that are built for maximum performance and longevity, giving them a competitive edge.

Eliminates Additives

Unlike traditional marking methods that use inks or dyes, UV lasers mark materials directly, eliminating the need for harmful chemicals or solvents. This ensures a cleaner, safer marking process for both your products and your workforce.

Eliminates Additives

Unlike traditional marking methods that use inks or dyes, UV lasers mark materials directly, eliminating the need for harmful chemicals or solvents. This ensures a cleaner, safer marking process for both your products and your workforce.

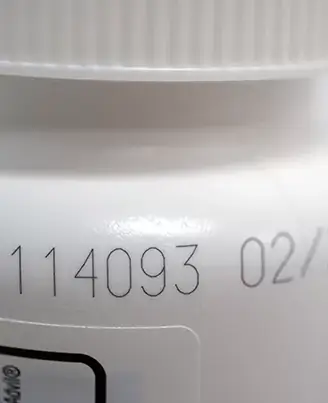

Superior Detail & Precision

UV lasers produce a highly focused beam of light, resulting in incredibly sharp and detailed markings. This makes them ideal for applications requiring intricate designs, small text, or high-resolution codes.

Superior Detail & Precision

UV lasers produce a highly focused beam of light, resulting in incredibly sharp and detailed markings. This makes them ideal for applications requiring intricate designs, small text, or high-resolution codes.

Precision Perfect Markings

Through suppressed heat effects, burrs and yellow tinting are eliminated, allowing for a nearly perfect finish.

Precision Perfect Markings

Through suppressed heat effects, burrs and yellow tinting are eliminated, allowing for a nearly perfect finish.

Reduced Risk of Micro-Fracture

The cold marking process of UV laser markers minimizes heat generation, preventing material warping or micro-fractures that can occur with traditional marking methods. This ensures the integrity and functionality of your marked products.

Reduced Risk of Micro-Fracture

The cold marking process of UV laser markers minimizes heat generation, preventing material warping or micro-fractures that can occur with traditional marking methods. This ensures the integrity and functionality of your marked products.

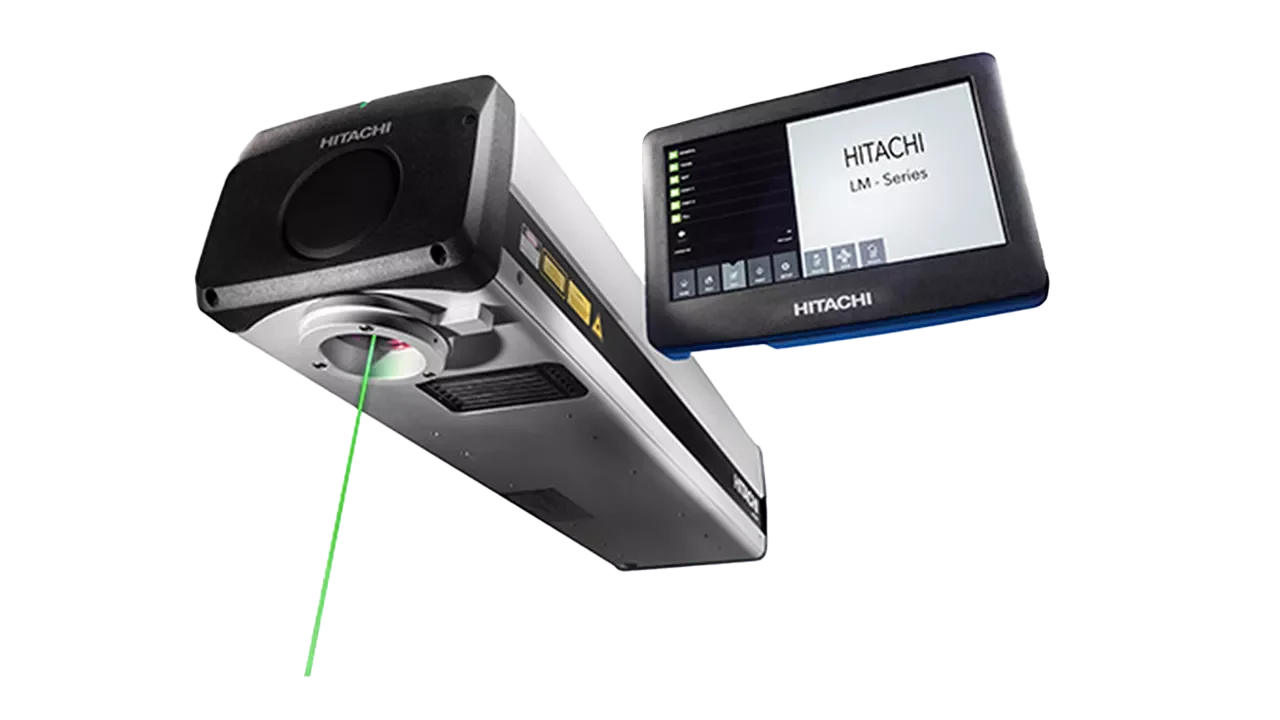

Space Saving

Our UV laser marking machine helps companies save space with its compact all-in-one marker and controller design.

Space Saving

Our UV laser marking machine helps companies save space with its compact all-in-one marker and controller design.

Easy Integration into Production Lines

UV laser marking systems are compact and require minimal setup. They offer seamless integration into existing production lines, allowing for efficient marking without interrupting your workflow.

Easy Integration into Production Lines

UV laser marking systems are compact and require minimal setup. They offer seamless integration into existing production lines, allowing for efficient marking without interrupting your workflow.

Streamlined Operation with Centralized Control

UV laser marking systems from Hitachi simplify your workflow with centralized control. Operate and manage your entire laser marking operation from a single, user-friendly platform. This eliminates the need for complex setups and allows for seamless integration into existing production lines.

Streamlined Operation with Centralized Control

UV laser marking systems from Hitachi simplify your workflow with centralized control. Operate and manage your entire laser marking operation from a single, user-friendly platform. This eliminates the need for complex setups and allows for seamless integration into existing production lines.

Reduced operational Costs

You can easily integrate this UV laser engraver into your existing production lines while eliminating everyday consumables, resulting in reduced operational costs.

Reduced operational Costs

You can easily integrate this UV laser engraver into your existing production lines while eliminating everyday consumables, resulting in reduced operational costs.

UV Packaging Laser Industrial Applications

Whether it's engraving on paper, plastics, metals, or non-metals, our UV laser engraving machines can mark various materials for a wide range of industry-specific packaging needs.

Applications of UV Laser Marking Machines

UV laser engraving machines offer high-precision micro-marking with exceptional resolution and sharpness on a variety of materials and substrates.

Helpful Resources

Put your production on the fast track with our feature-rich UV laser marking systems. Explore our extensive collection of resources, offering informative product videos, detailed brochures, technical specifications and data sheets, and inspiring customer success stories.

Get in Touch

Hitachi Industrial Equipment & Solutions America (HIESA) has sales offices strategically located in the Midwest and West Coast regions that specializes in providing primary and secondary packaging equipment and solutions. Beyond our immediate vicinity, we have a wide network of authorized sales partners that we work closely with to ensure that our packaging solutions are accessible to a broader customer base across the Americas and Canada.

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program