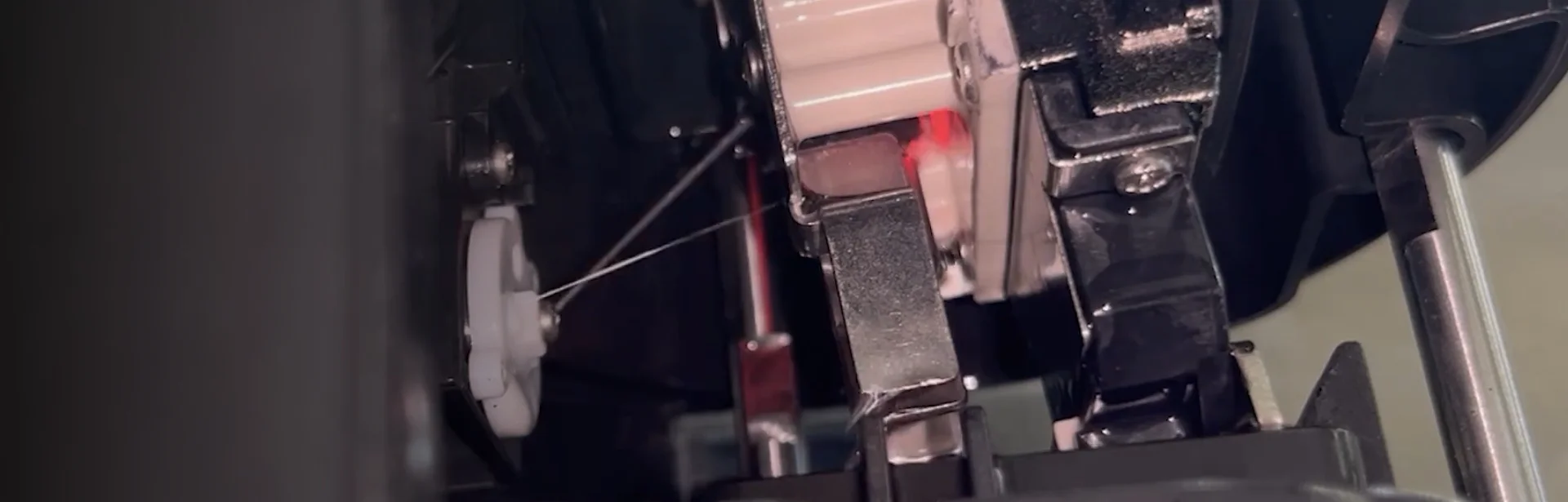

At Hitachi, we understand the importance of efficient equipment, and have taken this to heart in the design and development of our safe-clean station. One of the most common causes of extended downtime associated with CIJ is a dirty printhead. We have extended the uptime of our new UX2 printer with a totally new patented Ink Guard Printhead. Combining the Ink Guard with our Safe-Clean station results in a quick, efficient automated cleaning process, all without the need for open solvents on the production floor.

Hitachi’s Safe-Clean-Station is an accessory that seals, cleans, and dries the UX2 continuous ink jet (CIJ) printer’s printhead. Designed with three cleaning settings (Eco, Standard, or Deep Clean Mode), users determine the cleanliness and solvent used. Cleaning fluids are safely stored in a reservoir, the printhead is automatically dried with an internal air pump, and vapors are discharged through an exhaust duct. This eliminates open solvents when cleaning the printhead.

As a result, operators can be safe from exposure to chemicals, and save time. In addition, users can set up automatic ink recirculation during long periods of inactivity such as seasonal breaks/downtimes or for spare printers, allowing the CIJ printer to be ready to be used right away.

Primary Features

Discover the power of Safe-Clean Station with key features including three cleaning modes, an internal air pump system for rapid drying, and scheduled ink circulation, ensuring optimal performance and convenience.

Efficiently clean and dry the printhead with three available modes: Eco, Standard, and Deep Clean. Select the mode that matches the level of printhead dirtiness for standardized maintenance.

Users can perform a SMART start with the Safe-Clean Station. This will diagnose the cleanliness of the printhead nozzle. If dirty, makeup is reversed through the nozzle to remove dried ink buildup. The printhead will then start up, ensuring that the rest of the production schedule is met without issues.

When production shuts down for days, weeks or months, rest assured that your printer remains clog free. Keeping the printhead in the Safe-Cleaning Station and activating Hitachi’s auto-circulate mode ensures that all ink circulates periodically and remains ready for use. Customize the frequency from daily to weekly for optimal maintenance.

Traditional CIJ printers require the need for open solvent containers in order to clean dirty printheads. Hitachi’s Safe-Clean Station performs cleanings in a sealed environment that vents to exhaust ports. This reduces solvent exposure to workers as well as production equipment and food contact areas.

Specialty Features

Explore Safe-Clean Station's additional features, enhancing safety and promoting eco-friendly practices, further elevating your printer maintenance experience.

Maximize Operator Productivity

With Hitachi Safe-Clean Station, operators can simply insert the printhead, press a button, and step away, reducing manual cleaning time and freeing up valuable resources for other tasks.

Maximize Operator Productivity

With Hitachi Safe-Clean Station, operators can simply insert the printhead, press a button, and step away, reducing manual cleaning time and freeing up valuable resources for other tasks.

Enhance Operator Safety

Hitachi Safe-Clean Station is equipped with essential safety features that effectively extract harmful solvent vapors, safeguarding operators from exposure compared to traditional manual printhead cleanings.

Enhance Operator Safety

Hitachi Safe-Clean Station is equipped with essential safety features that effectively extract harmful solvent vapors, safeguarding operators from exposure compared to traditional manual printhead cleanings.

Minimal Training Required

Simply insert the CIJ printhead, press a button, and step away. No extensive training required, reducing the need for continual specialized training with workforce turnover, unlike traditional manual printhead cleanings.

Minimal Training Required

Simply insert the CIJ printhead, press a button, and step away. No extensive training required, reducing the need for continual specialized training with workforce turnover, unlike traditional manual printhead cleanings.

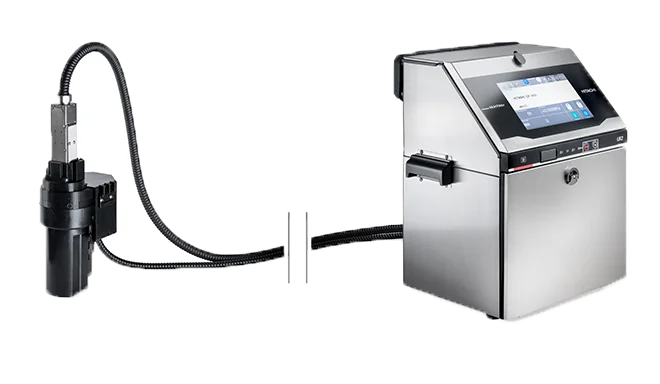

Mounting Station & 4.5 Meter Cord

Mount the Safe-Clean Station directly on the CIJ printer or positioned closer to the printhead for hassle-free cleaning wherever needed.

Mounting Station & 4.5 Meter Cord

Mount the Safe-Clean Station directly on the CIJ printer or positioned closer to the printhead for hassle-free cleaning wherever needed.

Minimize Printing Disruptions from Dirty Printheads

The Safe-Clean Station thoroughly removes ink buildup from vital printhead components, significantly lowering the risk of printing issues and downtime during printing operations.

Minimize Printing Disruptions from Dirty Printheads

The Safe-Clean Station thoroughly removes ink buildup from vital printhead components, significantly lowering the risk of printing issues and downtime during printing operations.

Build-in Cable Holder

The station features a dedicated holder to neatly store excess slack from the printhead cable, minimizing clutter and reducing the risk of tugging or snagging. This ensures the cable's integrity, promoting smooth and uninterrupted operation.

Build-in Cable Holder

The station features a dedicated holder to neatly store excess slack from the printhead cable, minimizing clutter and reducing the risk of tugging or snagging. This ensures the cable's integrity, promoting smooth and uninterrupted operation.

Smart Maintenance Functionalities

Automatically identifies and addresses issues such as ink stream misalignment and viscosity, the system will then implement corrective actions like nozzle backwash and viscosity corrections to maintain peak performance.

Smart Maintenance Functionalities

Automatically identifies and addresses issues such as ink stream misalignment and viscosity, the system will then implement corrective actions like nozzle backwash and viscosity corrections to maintain peak performance.

Why Choose Hitachi CIJ Printers

With an illustrious history of over four decades in industrial equipment and solutions, Hitachi is your esteemed partner for precision marking and coding solutions. Our unwavering commitment to quality, safety, and sustainability underpins the reliability of Hitachi Continuous Inkjet (CIJ) printers for variable data printing and other industry-specific marking and coding requirements. Fueled by advanced technology and continuous innovation, we offer unmatched customer support to help you boost production uptime and achieve operational excellence.

Ordering Information

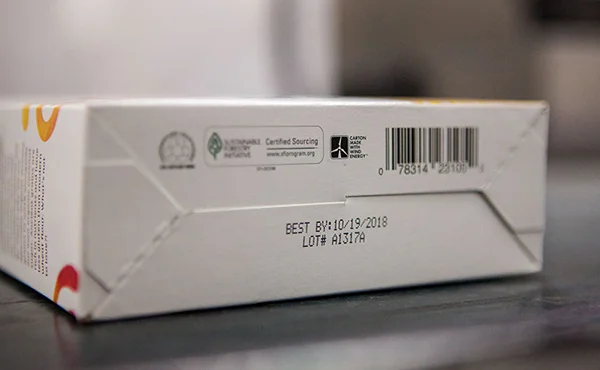

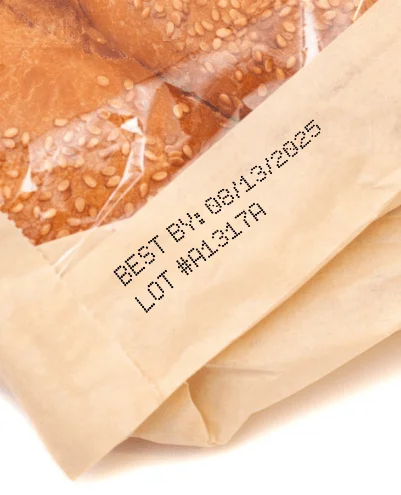

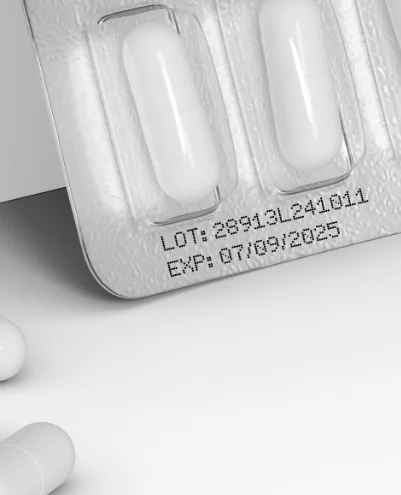

Common Printing & Packaging Applications

Our industrial inkjet printers excel in variable data printing such as batch codes, barcodes, expiry dates, serial numbers, and other unique product identifiers across various substrates and materials that are used in primary and secondary packaging, including flexible and rigid plastics, different types of metals, glass, cardboard, wood, paper, films, foils, and more.

CIJ Printers by Industries

Discover the unmatched capabilities of the Hitachi UX2 Series continuous inkjet printers, setting the standard for non-contact printing solutions across a broad spectrum of industries.

Helpful Resources

Put your production on the fast track with our feature-rich CIJ printers. Explore our extensive collection of resources, offering informative product videos, detailed brochures, technical specifications, and inspiring customer success stories.

Frequently Asked Questions (FAQs)

Find answers to commonly asked questions about the Continuous Inkjet printer - Safe Clean Station, its applications, and features.

The Safe-Clean Station is a unique feature of the Hitachi CIJ UX2 Series printers. It is a sealed system that thoroughly cleans and dries the print head in one simple operation, eliminating the need for open solvents. It captures and safely disposes of used solvent while preventing operator exposure to solvent gas through an air pump and exhaust duct.

Most of the downtime associated with inkjet printers is a result of a dirty nozzle. The self-diagnosis start-up with Safe Clean Station can be used to automatically clean the nozzle by reversing the flow of solvent when necessary. This ensures smooth restarts and consistent printer performance, enhancing efficiency and productivity in industrial marking and coding applications.

The Safe Clean Station is a unique feature exclusive to Hitachi UX2 Series CIJ printers. As manufacturers seek to improve production efficiency and offset rising supply chain costs, upgrading to Hitachi UX2 CIJ models can help achieve these goals and reduce the Total Cost of Ownership (TCO). To upgrade your existing CIJ printer, Learn More

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. To book a product demo or for any other query on our industrial printing solutions, leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

English

English

Portuguese

Portuguese

Spanish

Spanish