Baker Cheese Reduces Printing Costs and Downtime with Hitachi CIJ Printers

America’s Leading String Cheese producer adopts Hitachi Marking and Coding Solutions to improve their code date’s look that exceeded customer expectations.

Download Case Study

- Customer Name Baker Cheese

- Industry

Dairy

Dairy - Featured Products

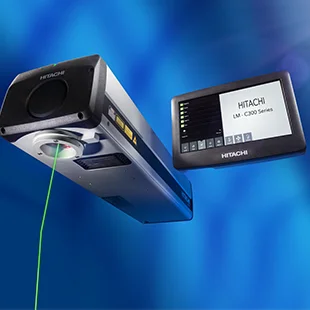

Hitachi Continuous Inkjet (CIJ) Printers

Hitachi Continuous Inkjet (CIJ) Printers

- Distributor IMS Partners

Summary

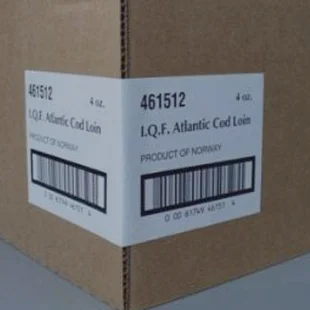

Baker Cheese needed to reduce downtime and increase print consistency in order to meet consumer expectations. After two weeks of head-to-head trials, they selected Hitachi RX Series Continuous Inkjet Printers as the clear winner. The result was an immediate improvement in uptime, decreased print costs, and reliable and consistent code dates allowing Baker Cheese to continue as one of America’s favorite string cheese producers.

About Baker Cheese A Family Tradition of Quality

Located in the heart of cheese country, you’ll find Baker Cheese; a 4th generation cheese producer. Baker Cheese pioneered the production of high-quality string cheese and has been a leading national producer for almost four decades. They take pride in the freshness of their cheese, owing that freshness to an astounding 48-hour farm-to-consumer ready process. This commitment to freshness and quality has been met with many awards and accolades from critics and consumers alike.

Business Challenges

Business Challenges

- Achieving a daily target of 3 million string cheese sticks daily.

- Existing coding equipment was very expensive to maintain & couldn't deliver consistent and high-quality prints.

- Production downtime due to stoppage can prove extremely costly & any new printer must be easy to use (for minimal downtime and efficient operation)

Solutions

Solutions

- Hitachi Continuous Inkjet Printers that seamlessly integrated with Baker Cheese’s intermittent motion production process, functioning within a small print window.

Outcome

Outcome

- Not only did the printers decrease downtime, they practically eliminated it, significantly improving production efficiency.

- Operational cost savings in printing.

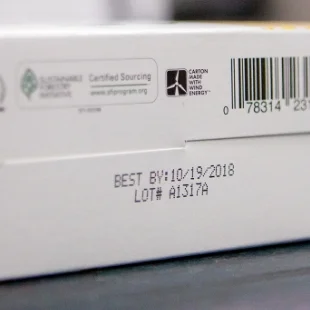

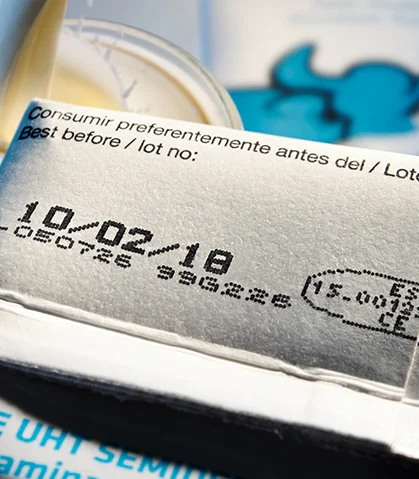

- Prints high-quality codes/code dates - transforming the look of code dates from average to exceptional, exceeding consumer expectations.

- Enhanced Baker Cheese’s brand reputation

Helpful Resources

From inconsistent markings to consistent, high-quality coding, explore how Hitachi’s advanced CIJ printers optimized Baker Cheese's production line.

Explore our Marking & Coding Solutions for the Dairy Industry

Baker Cheese Increases Production and Print Quality with the Hitachi RX Series Printers

Hitachi Webinar Series – How Technology Can Help Bridge The Gap During Labor Shortages

Hitachi Webinar Series – Understanding Total Cost Of Ownership Of Inkjet Printers

How Hitachi is Helping the Dairy Industry overcome their Marking & Coding Challenges?

From printing on glass and plastic bottles to plastic tubs, trays, and cartons, our reliable coding and marking solutions suit a multitude of primary and secondary packaging applications in the dairy industry. Safeguard the freshness of your dairy products.

Learn MoreSpeak to Our Experts

Call our Toll-Free number for expert guidance on choosing the best marking and coding equipment to meet your diverse industrial printing & packaging application needs.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. Leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

English

English

Portuguese

Portuguese

Spanish

Spanish