Giroux’s Farm Boosts Uptime and Cuts Marking Costs by 43% with Hitachi CIJ Printers

A fourth-generation egg producer cracks the code on efficiency, eliminates carton waste, and ultimately boosts up time.

Download Case Study

- Customer Name Giroux's Poultry Farm

- Industry

Egg

Egg - Featured Products

Hitachi Continuous Inkjet (CIJ) Printers

Hitachi Continuous Inkjet (CIJ) Printers

- Distributor Van Alstine

Summary

Giroux’s Poultry Farm needed to reduce downtime, operating costs, carton waste, and rejection rates associated with their coding equipment. After reviewing five competitive manufacturer’s printers they chose Hitachi to supply and install 28 Hitachi RX Series Continuous Ink Jet Printers. The result was an immediate improvement in uptime, a 43% reduction in operating costs, and the elimination of print-related carton waste.

About Giroux's Poultry Farm: Producing Quality Eggs for Over 60 Years

Giroux’s Poultry Farm is a 4th generation family-owned and operated business producing quality eggs for over 60 years. Located in the beautiful Champlain Valley, they are dedicated to providing a high-quality product through a fully integrated process from their hatchery and feed mill through production, packaging, and distribution.

Business Challenges

Business Challenges

- Traditional mechanical stampers required manual alignment and cleaning of stamps took 2 hours daily, limiting production capacity.

- Despite the time investment, stampers produced inconsistent and low-quality printing.

- Manual alignment also resulted in significant wasted cartons due to improper stamping.

- Stampers couldn't detect unclosed cartons, leading to additional waste and repackaging costs.

Solutions

Solutions

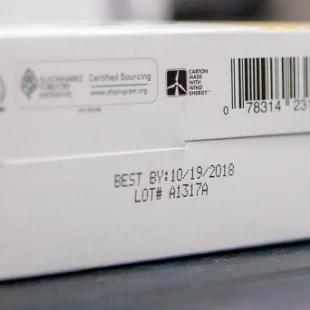

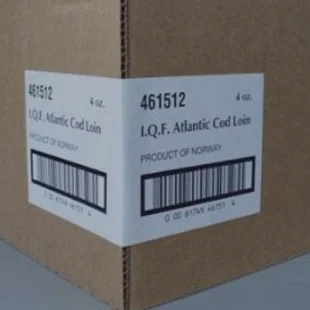

- Hitachi seamlessly integrated a fleet of 28 RX-SD160W inkjet coders, replacing Giroux's Poultry Farm's outdated mechanical stampers.

- This upgrade transformed their packaging line, exceeding their demands for reliability, print quality, and efficiency.

- Custom-designed mounting brackets ensured a perfect fit for each unit, delivering the immediate production and cost improvements they craved.

Outcome

Outcome

- 43% reduction in operating costs compared to the previous coder due to lower ink, make-up, and maintenance needs.

- Carton waste was eliminated through precise printing technology.

- Impressed by user-friendly design, consistent high-quality printing, and exceptional customer support, Giroux's Poultry Farm transitioned to a full fleet of 28 Hitachi CIJ printers, boosting overall production efficiency and reliability.

Helpful Resources

From frustrating stampers to streamlined efficiency, witness how Hitachi CIJ Printers transformed Giroux's Poultry Farm's egg and carton coding

Giroux’s Poultry Farm Reduce Product Marking Costs by 43% - Hitachi America, Ltd.

Hitachi Webinar Series – How Technology Can Help Bridge The Gap During Labor Shortages

How Hitachi is Helping the Egg Industry Overcome their Marking & Coding Challenges?

By streamlining the coding process, eliminating costly misprints, and ensuring each eggshell and egg carton gets a clear, reliable code it needs to meet regulations and safeguard your brand reputation.

Learn MoreSpeak to Our Experts

Call our Toll-Free number for expert guidance on choosing the best marking and coding equipment to meet your diverse industrial printing & packaging application needs.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. Leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

English

English

Portuguese

Portuguese

Spanish

Spanish