Coffee Producer Scores Coding Efficiency With Hitachi Continuous Inkjet Printers

New Inkjet Printers Cut Downtime for Steel Cans and Paperboard Trays at Massimo Zanetti

Download Case Study

- Customer Name Massimo Zanetti Beverages

- Industry

Beverage

Beverage - Featured Products

Hitachi Continuous Inkjet (CIJ) Printers

Hitachi Continuous Inkjet (CIJ) Printers

- Distributor Quattro R

Summary

Massimo Zanetti Beverage Group, a family-owned company with a passion for coffee spanning generations, manages every aspect of coffee production. Founded by Massimo Zanetti in the 1970s, the group has grown from a single roasting plant in Bologna, Italy, into a global coffee leader. Facing frequent downtime and inconsistent coding, Massimo Zanetti Beverage’s Suffolk, VA plant switched to Hitachi CIJ printers. The result? Significant production uptime, a 5% efficiency boost, crisp and reliable codes on all packaging, and cost savings. Hitachi's easy-to-use industrial printer kept their coffee flowing smoothly.

Business Challenges

Business Challenges

- Frequent maintenance and unreliable date coding systems caused production slowdowns at Massimo Zanetti Beverage's Suffolk facility. These stoppages impacted overall efficiency and product quality.

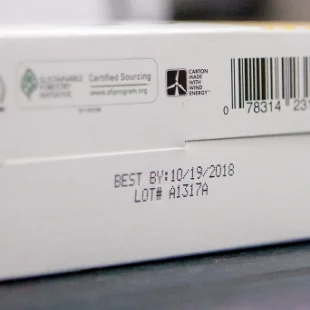

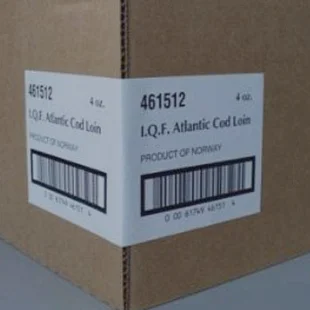

- The previous date coding machines struggled to deliver crisp, legible codes on diverse packaging materials, including paperboard trays and steel cans. This inconsistency raised concerns about product traceability and consumer information.

Solutions

Solutions

- Massimo Zanetti Beverage implemented Hitachi continuous inkjet (CIJ) printers across their production line. The printer’s efficiency ensure clear and consistent best-before-date printing on various packaging materials.

- The user-friendly touchscreen interface facilitated quick and easy code changes, allowing for adaptation to different products and customer requirements.

Outcome

Outcome

- The minimal daily maintenance requirements of the Hitachi inkjet printers significantly reduced unplanned downtime compared to their previous systems. This translated to increased production efficiency.

- Line efficiency rose by over 5% due to the reliability and user-friendliness of the Hitachi CIJ printers.

- The printers consistently delivered crisp and legible codes on even challenging surfaces like glossy paperboard trays, ensuring clear product information for consumers.

- Beyond reduced downtime, the Hitachi system offered cost savings on the printer inks compared to previous solutions.

Helpful Resources

Put your production on the fast track with our feature-rich industrial CIJ printers and other innovative marking & coding solutions. Explore our extensive collection of resources, offering informative product videos, product catalogs, industry brochures, and more.

How Hitachi is Helping the Beverage Industry Overcome their Marking & Coding Challenges?

Hitachi's user-friendly industrial inkjet printers minimize downtime and deliver high-quality codes on diverse packaging applications from glass and plastic bottles to kegs and cartons, keeping your beverage production worry-free.

Learn MoreSpeak to Our Experts

Call our Toll-Free number for expert guidance on choosing the best marking and coding equipment to meet your diverse industrial printing & packaging application needs.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. Leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

English

English

Portuguese

Portuguese

Spanish

Spanish