Ease of Use Makes the Hitachi Continuous Inkjet Printer a Holiday Treat at Sanders Candy

America’s Leading Candy Producer Chooses Hitachi Marking and Coding Solutions for Flawless Coding on Decorative Tins.

Download Case Study

- Customer Name Sanders Candy

- Industry

Candy & Confectionary

Candy & Confectionary - Featured Products

Hitachi Continuous Inkjet (CIJ) Printers

Hitachi Continuous Inkjet (CIJ) Printers

- Distributor Mark-Pack Inc

Summary

Due to business expansion, Sanders Candy turned to MarkPack Inc. for a better date coding solution than its laser and thermal transfer printers could provide. Mark-Pack placed one Hitachi continuous inkjet printer in a Sanders Candy production line. For the confectioner, it was better than a box of chocolates and they quickly ordered four more units, which performed flawlessly through the holiday peak production.

About Sanders Candy A Legacy of Sweet Success: Sanders Candy, Beloved for their Chocolate Bumpy Cake Since 1875, Chooses Hitachi for Reliable Coding on Decorative Tins

In business since 1875, Sanders Candy is top-tier technically and demands the best production and printing equipment. Famous for its Chocolate Bumpy Cake and other delicacies, this much-loved confectioner sought a better way to print on decorative tins of chocolate. The Hitachi distributor, Mark-Pack Inc., was certain Sanders’ technical team would love the Hitachi RX-S with its print quality, reliability, versatility, and easy programmability. About 20 minutes after arriving with a demo RX-S, Paul Owen of Mark-Pack had the Hitachi unboxed, up and running on a Sanders production line. Owen then let Sanders Candy techs take over and experiment with the unit for four days.

Business Challenges

Business Challenges

- As the holiday season loomed, Sanders Candy faced a coding crisis. Their existing laser printers marred the decorative tins' paint or couldn't print on the bottoms at all, leaving them with inconsistent and unacceptable codes.

- Running double shifts at 80 tins per minute, Sanders Candy needed a high-speed date coding machine to meet their holiday season demands.

Solutions

Solutions

- To meet peak Christmas demand, Sanders Candy expanded their Hitachi CIJ Printer fleet to four, replacing legacy laser printers and integrating them seamlessly across various packaging materials.

Outcome

Outcome

- Hitachi CIJ printers streamlined Sanders Candy's production, slashing costs by $465 per unit monthly and boosting output by 240-480 units daily by eliminating thermal transfer ribbons and saving 4 minutes per day.

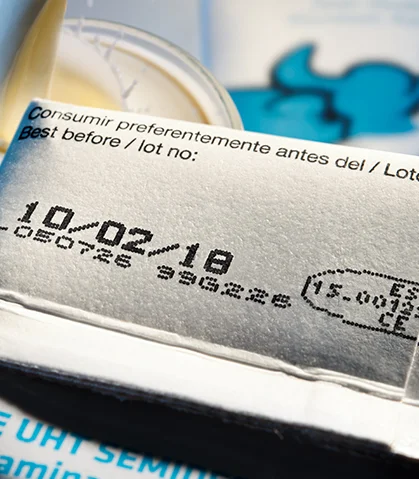

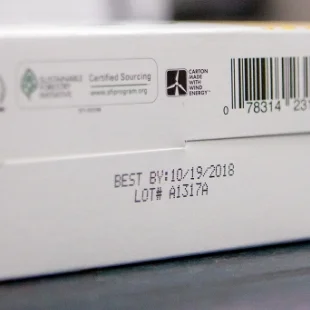

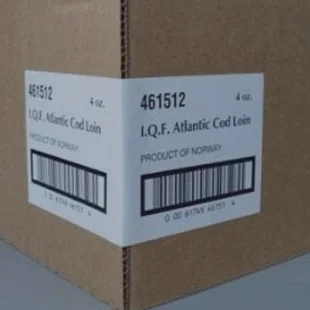

- Today, these printers ensure flawless coding efficiency on glass, plastic, flow wrappers, tins, and cartons during peak seasons.

Helpful Resources

Put your production on the fast track with our feature-rich industrial CIJ printers and other innovative marking & coding solutions. Explore our extensive collection of resources, offering informative product videos, product catalogs, industry brochures, and more.

How Hitachi is Helping the Candy & Confectionery Industry Overcome Their Marking & Coding Challenges?

From printing on metal cans to flow wrappers, tins, or tubs, our CIJ Printers help deliver crisp, reliable codes on various packaging materials to keep your confectionery production running smoothly.

Learn MoreSpeak to Our Experts

Call our Toll-Free number for expert guidance on choosing the best marking and coding equipment to meet your diverse industrial printing & packaging application needs.

Get in Touch

Connect with our knowledgeable team of technical experts to discuss your specific requirements and explore how Hitachi's Marking & Coding solutions can address your unique industry challenges and goals. Leave a comment, and we'll reach out to you as soon as possible.

The fields indicated with an asterisk (*) are required.

Hitachi Industrial Equipment & Solutions America, LLC

Hitachi Industrial Equipment & Solutions America, LLC

Request A Free Demo

Request A Free Demo

Print Sample Request

Print Sample Request

Video Gallery

Video Gallery

CIJ Replacement Program

CIJ Replacement Program

English

English

Portuguese

Portuguese

Spanish

Spanish